The textiles used for medical purposes is usually referred to as medical textiles. These textiles are mainly developed for non-aesthetic purpose rather than aesthetic purpose as the primary criterion. The introduction of medical textiles was due to the increased use of textiles in the field of medical technology. The impetus for need of medical textiles has arisen due to increasing population of elderly people and economic advancement in the developed and developing countries. These textiles act as an interface between the technical textiles and life sciences. Any advancements in this field leads to development in medical textiles. The developments like superabsorbent gel discovered in chemistry was a useful innovation for baby diapers and incontinence products. The developments in the field of textile engineering have led to invention of 3D spacer fabrics which have found their usage in bandages.

History and Development

The use of textiles in medicine could be traced back to ancient Egyptian era where natural rubber adhesive and flax yarn were used to suture the wound. The mummies were prevented from decaying by chemical treatment of linen wrappings. Ancient Chinese texts also depict the use of flax fibre for suture and cotton cloth to stop bleeding. During 5000 AD hand woven cloths and spider webs were used to prevent bleeding. India also has a history of use of wide variety of textile materials for suturing like horseback, leather strips, animal sinews, cotton and fibrous trees. Wide variety of textile structures like woven, knitted, braided and nonwoven have found their use in medical textiles. The recent years have seen advancements in the type of textile materials to be used as medical textiles. The paradigm shift has been observed by introduction of synthetic fibres in the medical field. Advancements in the biodegradable fibres like chitin, polylactic acid etc have made ample progress in medical field. The biodegradable sutures have been in great demand to suture the wounds and for most surgical incisions. With the utilisation of nonwoven fabrics, synthetic fibres expanded their scope of application in the medical field. In recent years, medical textiles have advanced from surgical gowns and wound dressings to skin grafts, stents, artificial organs and other healthcare products.

Classification of Medical Textiles

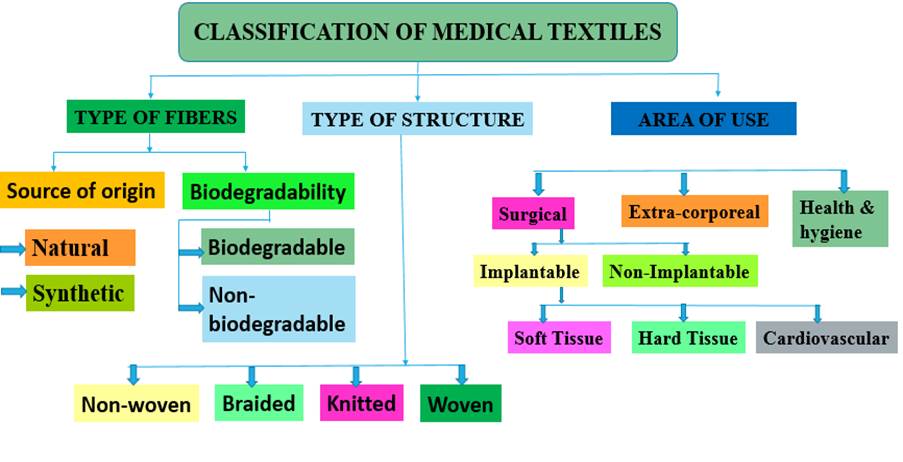

The medical textiles could be classified into various categories based on types of fibres, type of textile structures, and area of use. The classification of textiles based on these categories is presented in the figure below:

Classification Based on Types of Fibre

According to the Source of Origin

|

Natural |

Synthetic |

|

Cotton, Silk, Linen, Lyocell, Alginate, Chitin etc. |

Polyester, Polypropylene, Polyamides, Polyethylene fibres, Silicon fibre, Poly methyl methacrylate fibre, Polylactide, Poly glycolide, Polyurethane, carbon, glass etc. |

According to Biodegradability

|

Biodegradable |

Non-Biodegradable |

|

Cotton, Silk, Chitin, Viscose, Polyamide, Polyurethane, Collagen, Alginate, Polylactic Acid (Poly Caprolactone) Polyglyconic Acid |

Polypropylene, PTFE, Carbon etc. |

Classification Based on Types of Fabric Structure

The fabric properties usually depend on the characteristics of yarns, fibres and geometry of the fabric structure. The properties of medical textiles depend on fabric structures like woven, knitted, braided or nonwoven structures.

Woven Fabric

Woven fabrics could be considered as dimensionally stable structures with less extensibility and porosity than other textile structures. The limitation of woven textiles is due to their tendency to unravel at the edges if they are cut in square or oblique shape for implantation purpose. But evolution of leno weave in formation of textile structures has provided solution to the problem of fraying. The bandages, vascular plugs, vascular grafts, tissue scaffolds and artificial ligaments are such woven textiles used in medical field. The applications include, vascular plugs, vascular grafts, tissue scaffolds, artificial ligament etc.

Knitted Fabric

Knitted fabrics structures could be weft knitted or warp knitted. The weft knitted structures have high extensibility,but are considered as dimensionally unstable unless extra interlocking yarns are added to the structures, which increases elastic recovery. The warp knitted structures are versatile and could attain the mechanical properties similar to woven fabrics. The main advantage of knitted structures over woven structure is flexibility and their ability to resist ravelling when cut. The limitation of knitted structures includes high porosity which cannot be reduced below specific value. The applications include surgical meshes, adhesion barriers etc.

Braided Structure

The braided structures have found their use in cords and sutures using different patterns with or without the core component. The main feature of these structures includes porous nature which helps to imbibe the fluids using the interstitial spaces present between the yarns or filaments in the braided structure. The capillarity of the braided structures could also be controlled through treatment with compounds like polylactic acid or Teflon coating. These coatings are also helpful to reduce the noise during body movement and enhance the properties of braided structures. These treatments also help to position the knots of the suture when pressure is applied by surgeon’s finger. The applications include stents, suture etc.

Nonwoven Structure

The nonwoven structures have found variety of use in the medical textiles. The end uses are determined by the properties of the polymer or fibres used and the bonding process used for construction of the nonwoven textile structures. For example, the polymer Polytetrafluoroethylene has found use in medical textiles due to its hydrophobic and expanding nature of micro-structure. These materials when used in sutures tend to compress easily and then expand allowing the ingrowth of tissues in arterial and patch grafts. The polyurethane-based nonwovens also resemble collagenous materials and are used in medical textiles. The applications include diapers, sanitary pads, surgical gowns, surgical caps etc.

Classification Based on Area of Use

Implantable Materials

The textile structures like fibres, yarns, fabrics, composite structures and 3-D shaped fabrics have pivotal role in manufacturing of various implants of non-functioning blood vessels, aorta segments, and arteries. The introduction of textiles in medical field has led to development of vascular prosthesis (2-3 mm in diameter). The vascular prosthesis is helpful in wound closure or in replacement surgery through vascular grafts, artificial ligaments and other medical textiles.

The main feature of implantable material is biocompatibility which refers to acceptance of human body. The acceptance of implants is determined by key factors like:

• Porous nature of implants which determine the tissue growth for encapsulation of implant by human body.

• The small circular fibres to be used as implants rather than large fibres with irregular cross-sections for better encapsulation in human tissues.

• The polymers to be used in medical textiles should not release any toxic substance and should be free from any impurities and contaminants.

Non-Implantable Materials

The non-implantable textile materials are generally used for external body applications. The materials are usually synthesised from the copolymers two α amino acids. The applications involve bandages, orthopaedic belts, compression garments etc.

Extra Corporeal Devices

The medical textiles which are considered as extracorporeally mounted devices are generally used to support body organs like heart pacer, lungs, liver, kidney etc. These devices are mechanical organs which support the functioning of vital organs. The applications include, artificial kidney, mechanical lungs, artificial liver etc.

Healthcare And Hygiene Products

The healthcare and hygiene sector is among the important medical applications. The main use of medical textiles in healthcare and hygiene is for care and safety of hospital staff and patients. These products could be disposable or washable. The applications include surgical gowns, caps, patient drapes, mattress covers, wipes etc. These medical textiles help in prevention of cross infection among the patients. The incontinence products like sanitary napkins, adult diapers and baby diapers are also among important end uses of textile materials in medical field.

Textiles According to Area of Use

Implantable Materials

|

Fibre Type |

Fabric Structure |

Applications |

|

Collagen, Catgut, Poly Glycolide And Polylactide Fibre |

Monofilament, Braided |

Biodegradable Sutures |

|

Polyester Fibre, Polyamide Fibre, PTFE Fibre, Polypropylene Fibre, Polyethylene Fibre |

Monofilament, Braided |

Non-Biodegradable Sutures |

|

PTFE Fibre, Polyester Fibre, Silk, Collagen, Polyethylene Fibre, Polyamide Fibre |

Woven, Braided |

Artificial Tendon |

|

Polyester, Carbon Fibre, Collagen |

Braided |

Artificial Ligament |

|

Low Density Polyethylene Fibre, Chitin |

Nonwoven |

Artificial Skin, Artificial Cartilage |

|

Poly (Methyl Methacrylate) Fibre, Silicon Fibre, Collagen |

Films |

Eye Contact Lenses, Artificial Cornea |

|

Silicon, Polyacetyl Fibre, Polyethylene Fibre |

Films |

Artificial Joints/ Bones |

|

PTFE Fibre, Polyester Fibre |

Woven, Knitted |

Vascular Grafts |

|

Polyester Fibre |

Woven, Knitted |

Heart Valves |

Non-Implantable Materials

|

Fibre Type |

Fabric Structure |

Applications |

|

Cotton, Viscose, Lyocell |

Nonwoven |

Absorbent Pads |

|

Alginate Fibre, Chitosan, Viscose, Lyocell, Cotton |

Woven, Nonwoven, Knitted |

Wound Contact Layer |

|

Viscose, Lyocell, Plastic Film |

Woven, Nonwoven |

Base Material |

|

Cotton, Viscose, Lyocell, Polyamide Fibre, Elastomeric Fibre |

Woven, Nonwoven |

Simple Non-Elastic and Elastic Bandages |

|

Cotton, Viscose, Lyocell, Elastomeric Fibre |

Woven, Nonwoven, Knitted |

High Support Bandages |

|

Cotton, Viscose, Lyocell, Elastomeric Fibre |

Woven, Nonwoven, Knitted |

Compression Bandages |

|

Cotton, Viscose, Lyocell, Polyester, Polypropylene, Polyurethane Foam |

Woven, Knitted |

Orthopaedic Bandages |

|

Cotton, Viscose, Plastic Film, Polyester Fibre, Glass Fibre, Polypropylene Fibre |

Woven, Nonwoven, Knitted |

Plasters |

|

Cotton, Viscose, Lyocell, Alginate Fibre, Chitosan |

Woven, Nonwoven, Knitted |

Gauge Dressing |

|

Viscose, Cotton Linters, Wood Pulp |

Nonwoven |

Wadding |

|

Polylactide Fibre, Polyglycolide Fibre, Carbon |

Spunlaid, Needle punched Nonwoven |

Scaffold |

Extracorporeal Devices

|

Fibre Type |

Applications |

Function |

|

Hollow Polyester Fibre, Hollow Viscose |

Artificial Kidney |

Remove waste products from Patients’ blood |

|

Hollow Viscose |

Artificial Liver |

Separate and dispose of patients plasma and supply fresh plasma |

|

Hollow Polypropylene Fibre, Hollow Silicone Membrane |

Mechanical Lung |

Remove carbon dioxide from patients’ blood and supply fresh oxygen |

Healthcare / Hygiene Products

|

Fibre Type |

Fabric Structure |

Applications |

|

Cotton, Polyester Fibre, Polypropylene Fibre |

Woven, Nonwoven |

Surgical Gowns |

|

Viscose |

Nonwoven |

Surgical Caps |

|

Viscose, Polyester Fibre, Glass Fibre |

Nonwoven |

Surgical Masks |

|

Polyester And Polyethylene |

Woven, Nonwoven |

Surgical Drapes, Clothes |

|

Cotton, Polyester Fibre, Polyamide and Elastomeric Fibre |

Knitted |

Surgical Hosiery |

|

Cotton, Polyester Fibre |

Woven, Knitted |

Blankets |

|

Cotton |

Woven |

Sheets, Pillow Cover |

|

Cotton, Polyester Fibre |

Woven |

Uniforms |

|

Polyester Fibre, Polypropylene Fibre |

Nonwoven |

Protective Clothing, Incontinence Diaper/ Sheet |

|

Superabsorbent Fibres, Wood Pulp |

Nonwoven |

Absorbent Layer |

|

Viscose, Lyocell |

Nonwoven |

Cloth Wipes |

Basic Requirements of Textiles in Medical Field

The textiles used in medical field should have the following properties to increase the efficiency of the medical textiles.

-

Biocompatibility

-

Flexibility

-

Strength

-

Sterile

-

Anti-allergic

-

Anti-bacterial

-

Environmentfriendly

-

Economical aspect

Advantages of Textiles in Medical Field

• Flexible, comfortable and soft

• Breathable

• Reduced cross infection

• Cost-effective

• Protection from static electricity generated in operation theatres

• Biocompatible

• Safety of medical staff and patients

• Allow easy movement of body parts

Conclusion

Demographic changes, increase in the population of elderly people, and need for increase in life expectancy have led to advancement in the field of medical textiles. The advancement in the literacy rate and education standards has changed the attitude of people towards health risks and increased awareness of associated risks. Medical textiles includes the use of textile fibres and polymers in various end uses ranging from a suture to bandages, stents, incontinence products, healthcare products and artificial organs. The competition among leading brands and suppliers has further increased the end use availability of the medical textiles. The wide variety and types of medical textiles has also led to more research and development in the textile sector.

- Qin, Y. (2016). Medical Textile Materials. Woodhead Publishing, Cambridge, p 2-20.

- Bartels, V. (2) (2011). Handbook of Medical Textiles. Woodhead Publishing, Cambridge, p 15-45.

- Gopalakrishnan, D. (2023). Recent Developments in Medical Textiles [Internet]. Available from: http://www.fibre2fashion.com/industry-article/1466/recent-developments-in-medical-textiles?page=3 [Accessed 25 September 2023].

- An Analysis of Medical Textiles [Internet]. Available from : http://www.technicaltextile.net/articles/medical-textiles/detail.aspx?article_id= 3035& page no=3

- Introduction of Medical Textiles [Internet]. Available from: http://textilelearner.blogspot.in/2012/02/introduction-of-medical-textiles.html .

- Czajka, R. (2005). Development of Medical Textile Market. Fibers and Textiles in Eastern Europe. 13, No.1(49) January, pp 13-15.