Man is not very old to forget the invention of wheel, andthe wave of time is not out of the scene to find it hard when recalling thebeginning of computer age. Now we are at the onset of new era of science thatexplores the behavior of material at their bottom, set new topics in technicalapplications of polymeric materials, and expose immense opportunities in theperformance and application of materials.

Nanotechnology has currently received an exceptionalinterest of researchers, technology incubators and commercial organizations tostep forward in introducing the materials having nanocomposite structure andnew performance standards.

Investigating the smallest possible particles had providedthe opportunity of exploring new performance standards for materials. Newdimensions are appearing in material processing and applications in mostdisciplines of science and technology and the field of textile has noexception. From the production of synthetic fibers from polymer melt to thespecial finishing effects of fabric substrates, nanoparticles are occupying thepositions in producing the composite structure for desired effects.

Atom is known to the world since the introduction ofclassical science age as an elementary unit of any material, however the functioningof material was perceived in most cases in terms of aggregate structures. Therecent onset of nanotechnology is now demonstrating the material performance onthe basis of very small particles that are having size range of fewernanometers.

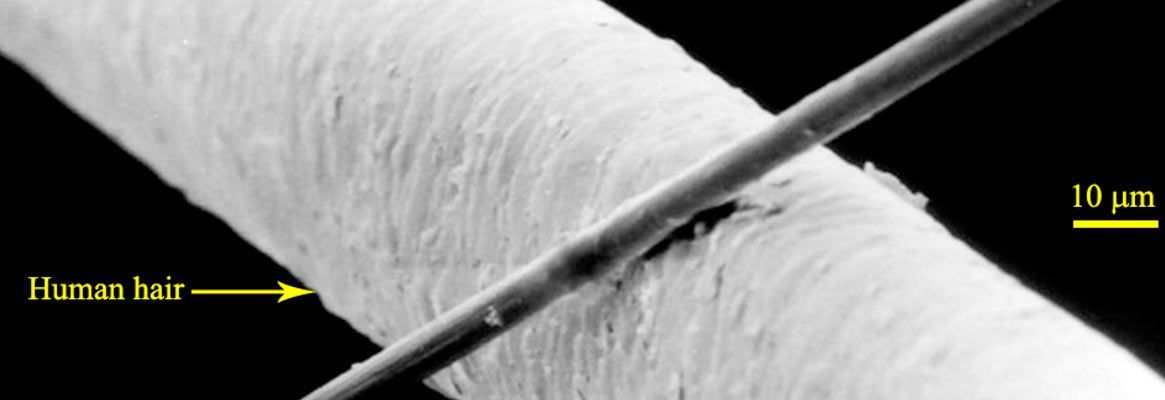

The word nano in nanotechnology has origin in Greek wordnanos meaning dwarf (small). Prefix nano means one-billionth part, i.e. 10-9,for example one nanometer is one-billionth part of a meter. How large is onenanometer! Perhaps it can be imagined by the diameter of single human hairwhich is approximately 100,000 times greater than one nanometer. Nanoparticlesare atomic assembly that exhibits outstandingly different behavior than thebulk of material. An example may be seen in ceramics which are known as brittleand rigid materials. A ceramic material can be made deformable when theirconstituent grain size is reduced to low nanometer range. Also, a small amountof nanoparticles of a substance when included in a polymer matrix havingsimilar size range the resulting system exhibits an exceptional performancelevel (1).

Nanotechnologies can be perceived as the design,characterization, production, and application of structures, devices, andsystems by controlling shape and size of material particles on nanometer scale(2). The origin of nanotechnology can be traced to a talk given by RichardFeynman on 29th December 1959 at the annual meeting of the AmericanPhysical Society at the California Institute of Technology, U.S.A., on the topic of There is Plenty of Room at the Bottom. Further, the termnanotechnology was introduced by Norio Taniguchi, Tokyo University, almost 15years after in 1974. The concept was expanded by Eric Dreklor, MIT, USA in 1986 through his book Engines of Creation: the Coming Era of nanotechnology.Subsequently, nanoscience then became the study of phenomena and manipulationof materials at atomic (0.2nm approx), molecular or macromolecular scales(around 100nm).

Why to see that magnificent change in the performance ofmaterial at nanoscale! This is the result of relatively significant increasedsurface area-to-mass ratio. The same material becomes more chemically reactiveand exhibits different physical properties. Moreover, below the particle sizeof 50 nm, the laws of classical physics follow quantum effects that result indifferent optical, electrical and magnetic performance relative to the largesize structure of same material (2).

There is no single branch of science and technology orindustry that is not affected by nanotechnology. The development andinnovations in the next 10 years or so would even be showing stronger influenceof nanotechnology on most materials we are surrounded. To date, it hasaccommodated the multiplication of applications in material manufacturing (moreimportantly in polymer modification and synthesis), and computer/electronicchips, medical diagnosis, health care, finishing formulations, energy,automations, biotechnology, packaging, space, aircrafts, protection andsecurity.

In automotives, perhaps the Toyota and General Motor have the leading positions in using nanocomposites. Toyota introduced first polymer/ clay auto parts in 1980s (3). General Motor stepped up to bring nanocomposite on road by launching first commercial auto exterior use of a nanocomposite in 2002 GMC Safari and Chevrolet Astro Van (4). The nanocomposite part was also on 2003, 2004 models. General Motors highest volume car, the 2004- Chevrolet Impala has body side molding composed of PP/nanoclay composite. The latest example was seen on 2005 GM Hummer H2 SUT; its cargo bed used around seven pounds of molded-in- color nanocomposite parts.

The performance enhancement occurs when nanoparticles are introduced in a material i.e. making them the part of material structure; and this has changed the composition of several thermoplastic polymers for variety of applications. Nanocomposites that are currently used in polymers are based on nanoclays, carbon nanotubes (CNT), carbon nanoparticles and metal hydroxide. Nanocompsite fibers may be based on nonosize fillers/ particles including clay, metal oxides, carbon black, carbon nanotubes and graphite nanofibers (1).

Fibers and polymers/ plastics that can resist heat, chemicals, corrosion, fire, UV light, impact etc., are now possible with nanocomposites both for consumer products and high performance applications.

Polymers reinforced with 2-5 wt% of nanoclays may exhibit significant improvement in thermal- mechanical properties, flame retardancy, barrier properties, dimensional stability, and modified electrical conductivity. An interesting example is seem in nylon-6 nanocomposite reinforced with 5 wt % of nanoclay resulting in 40% increase in tensile strength, 68% in tensile modulus, 60% in flexural strength, and 126% flexural modulus. The heat distortion temperature increases from 65 0C to 152 0C (5).

Being in nanometer size range, small amount of nanofillers possess high surface area. For example commercially a nanoclay product with surface area of 750 m2/gram (=an area corresponding to an equivalent area occupied by 9 soccer fields approximately) is known (6). Therefore, evenly distributed small amount of nanofiller may interfere with the polymer chain- its movement and reaction to external reagents and physical factors; and ultimately giving enhancement in the polymer toughness, strength and resistance to heat and chemicals.

Biological protective textiles can be produced using nanoparticle form of TiO2, and MgO. Photo- catalytic activity of Ti O2 and MgO can decompose harmful and toxic chemicals and biological agents. Textile finishing using nanoparticles can convert fabric into sensor- based materials.

Nanocarbons are nanosized carbon- based materials that can be bonded at molecular level of a material in various ways, producing unique properties in the material (7). The nanocarbon family may include carbon nanofiber, carbon black nanoparticles, fullerenes, carbon nanotubes etc.

Carbon nanofiber and carbon nanoparticles both may enhance the chemical resistance and electrical conductivity of composite fibers (1), apart from modifying the strength and toughness. Carbon nanotubes (CNT) consist of long, thin cylinder of carbon whose diameter (usually few nanometer) is significantly smaller than the length (several millimeter), therefore the length- to- diameter ratio (aspect ratio) is very high. CNTs are tiny shells of graphite rolled up in cylinder. These could be single walled (SWNT) or multi- walled (MWNT) and exhibit exceptional properties. The structure of multi- walled tubes is like cylinder inside other cylinder.

The electronic, thermal, and structural properties of CNTs depend upon the length, diameter, and twist of the nanotube (8). The properties exhibited by the CNTs are very interesting and an enormous volume of research is currently underway. For example their tensile strength is 100 times of steel at 1/6th weight. CNTs are studied in the domain of textiles to expand the applications of synthetic fibers including polyvinyl alcohol, polymethylmethacrylate, and polyacrylonitrile. However, there are several other application areas where CNTs are currently investigated to enhance the desired effects or to achieve multiple performance effects in devices. Such applications are in the nanometer-sized semiconductor devices, probes; sensors; conductive and high-strength specialist composites; devices for energy storage/ conversion; development of lubricants, coatings, catalysts; electro-optical devices, and medical applications.

The expansion in nanotechnology development may be imagined from the sales of emerging nanotechnology products that were 0.1 % of global manufacturing output in 2005, and estimated to reach 15% by 2014. From 2010- onwards the presence of nanotechnology would be visible in most manufactured goods or high- end products Venture Capitalists had invested US $ 1 billion in nanocompanies by the end of 2004 (2).

In 2003, nanotechnology was generating US $ 385 million annually in business in USA, and this volume is expected to reach US $ 3.5 billion by 2008, and US $ 20 billion by 2013 (9).

Chemical finishes, textile processing and finished textile products form an important area of nanotechnology. Synthetic fibers are gaining interest to modify for smarter applications using nanoclays (montmorillonite) and carbon nanotubes. However, the use of nanochemical finishes offers options to modify both natural and synthetic fibers.

Nanoclays are the viable source of modifying the fibers and polymers for a range of applications and are increasingly taking greater role in replacing undesired halogenated flame retardants for traditional and technical applications. The consumption of clay nanocopmosite, in 2005, accounted for almost one- quarter (24 %) of total nanocomposite consumption. The nanoclay composites are projected to raise their market share to 44 % by 2011 (3). These figures clearly indicate the interest and importance of nanoclay composite.

The commercial viability of nanoclays is mainly credited to their reduced cost (around US $ 2.25- US $ 3.25 per pound), wider applicability to most synthetic polymers (PP, TPO, PET, PE, PS, polyamide), and performance enhancement produced in end- product.

Montmorillonite clay is an extensively employed type of clay used in modifying the polymeric materials. Montmorillonite clay is a strong absorbent of minerals and heavy metals and prior the introduction of nanoclay composite it had been used for improving health including energy, stamina, smoother skin complexion, healing of bleeding gums, cavities, and wounds (10).

There may be a concern somewhere to know more about the discipline of nanotechnology, particularly for research and development work. A comprehensive report (2) had indicated that at nanoscale, chemistry, biology, electronics, physics, material science, and engineering start to converge and the distinction as to which property a particular discipline measures no longer applied. All these disciplines are contributing to the understanding of possibilities offered by nanotechnology.

We are surrounded with fiber- and polymer- based materials.

From clothing to car, and from home to factory, the materials constituting

physical environment consume significant volume and types of fibers and

polymers. Nanocomposite polymers and fibers would increasingly become the part

of our physical world exhibiting new performance standards. Primarily the

nanotechnology is perceivable as the art of innovative advanced technology,

however the producers and processors of traditional products in textile and

polymer sector and the associated policy organizations in developing regions

have much to accommodate to meet the opportunities and threats.

Like any other technology, there are concerns on the health, environment and safety risks associated with the nanotechnology. The manufactured nanoparticles may enter the human body through various ways, and may possibly harm tissue or reach vital organs via the blood circulation. However, the risks shown by the nanoparticles in free state can not be the same when they are in bulk form for example nanocomposite materials or when the particles are in polymer structure. The precision of risks factors, if any, associated with nanoparticles are possibly in process by the regulatory assessment. The toxicity of nano- particles and carbon nano- tubes; the risks of nanomaterials, and standardization are receiving concerns (11). Size effects are not addressed in the frame work of the new European Chemical Policy (REACH). Possibly such assessments for nanocomposites are the matter of time until more advanced studies are known.

However, the development and expansion in nanoparticles and nanocomposite are already going along several existing health and safety standards at work places, at least in industrialized countries, therefore it is unlikely that future would eliminate nanotechnology (12).

References:

1) Lei Qian; Juan P. Hinestroza; Journal of Textile and Apparel Technology and Management, Volume 4, Issue 1, (Summer 2004), 1- 4.

2) Christoph Lauterwasser, Editor; Opportunities and Risks of Nanotechnologies- Allianz Report in Cooperation with the OECD International Future Program, (June 2005), 3- 6, 35.

3) Andrew McWillians, Nanocomposite, Nanoparticles, Nanoclays, and Nanotubes, Research Report # GB- NAN021C, Home Page www.electronics.ca

4) Lilli Manolis Sherman, Plastic Technology, Home Page, www.ptonline.com, accessed June 15, 2007.

5) Charles A. Wilkie, General Considerations on the Use of Fillers and Nanocomposites, Home Page, www.rsc.org, July 2007, 5.

6) Closite ref.. CloisiteR Additives: Nano- Scale Additives for Reinforced Plastics, Southern Clay Products, Home Page www.nanoclay.com, accessed July 9, 2007.

7) Home page, www.nanocarbontechnology.com, accessed July 11, 2007.

8) Ottilia Saxl, Making the most of carbon nanotubes- the miracle material of the 21st century? Home page, www.nano.org.uk, accessed July 11, 2007.

9) Katrina C. Arabe, Nanomaterials Set for Explosive Growth, (September 11, 2003), Home Page, www.news.thomasnet.com, accessed June 07, 2007.

10) Montmorillonite Clay, Home Page,www.symmetry4u.com, accessed July 9, 2007.

11) Anon., Textile Asia, (January 2006), 29.

12) Faheem Uddin, Clays, nanoclays, and montmorillonite minerals, in press for publication, (2007).

About the Author:

Dr. Faheem Uddin is associated with the Department of Textiles, School of Science and Technology, University of Management and Technology, Lahore, Pakistan.

To read more articles on Textile, Industry, Technical Textile, Dyes & Chemicals, Machinery, Fashion, Apparel, Technology, Retail, Leather, Footwear & Jewellery, Software and General please visit http://articles.fibre2fashion.com

To promote your company, product and services via promotional article, follow

this link: http://www.fibre2fashion.com/services/article-writing-service/content-promotion-services.asp