A research says that one out ofevery five people suffer from body odour. Sweating is a way by which our bodyrelieves itself from its heat. Sweat does not have an odour by itself. It isthe bacteria living in our skin that works with the sweat and create acidswhich produce odour.

Omikenshi Co., Ltd, a Japanese basedfirm, manufactures a number of fibres that are quoted with materials obtainedin a natural way from plants and animals. These fibres are anti bacterial andanti allergic in nature and exhibit deodorizing abilities when exposed tosunlight.

Sundia branded fibres:These fibres possess antibacterial abilities. It has the ability to fightbacteria and hence these viscose fibres can be used for manufacturing aromaticfabrics that can control body odour and also good for people who wish to avoidultra violet radiation. The deodorizing effect is obtained when the fabric isexposed to sunlight for minimum five hours.

Crabyon branded fibres:They are manufactured from a material called Chitosan derived from Chitin, obtainedfrom the shells of crab and shellfish. These fibres are anti allergic, antimicrobic and anti bacterial, and are capable to fight bacteria and other germs.Easiness of manufacturing and quickness in dyeing are its plus points. The antiallergic and high moisture absorption qualities of this fabric enhances its capabilityto be used in manufacturing garments which has direct skin contact, babyclothes, sports wear etc.

Kishu Binchotan fibres: Theyare made from the materials obtained from viscose and charcoal derived fromoven-baked oak. These fibres provide protection against body odour, and alsosupport blood circulation by discharging infrared radiation.

Fruity Fabric: OmikenshiCo has developed a rayon fibre manufactured with emulsified grape fruit extractand has a strong aroma of grapes. This fabric is distinguished from the otherones manufactured with aromatic capsules attached to it. The aromatic solutionis mixed and the rayon fibres are weaved, which enables a fruity fragrance tofloat out through small openings in the garment.

Researches are further being madeto explore the options of manufacturing special fibres from squalene, amaterial derived from sharks liver. Squalene plays a vital role insafeguarding a persons health. Daiwabo, another Japanese based company hasmanufactured a new deodorant called Deometafi which is able to form ionic bondswith the fibres and can control body odour.

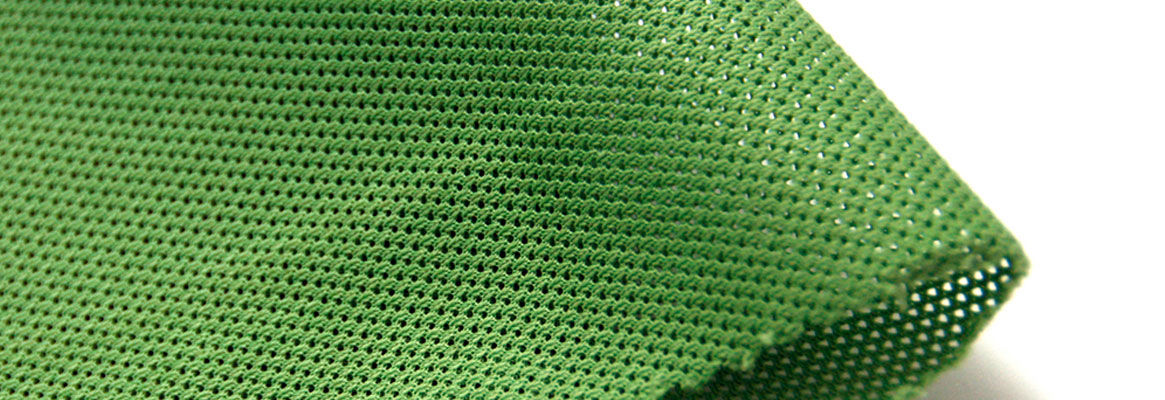

Teijin Company has now developeda new fibre based on polylactic acid which is heat stable and is a goodalternative to traditional polyesters. Ecocircle, a new system for recyclingold and discarded synthetic garments is also adopted by them. They have also developednew polyester for making sports wear which can absorb and let the moisture outvery quickly.

Morpho fibres: Furthermore, Teijn has developed a photo chromic morpho fibre that builds variouscolors by light inter-ference. It is a structurally colored fibre comprising ofnylon or polyester, having 61 layers in four basic colors of red, yellow, blueand green. This color producing concept is evolved from male Morpho sulkowskyibutterfly of the tropical North American regions renowned for its bright bluecolored wings. Vibrant colors would then be produced without using anyartificial chemicals or dyes.

Three Japanese companies havedeveloped a polyester fabric as an alternative of polyurethane (PU) foam, which can be used as cushioningmaterial in furnitures. Polyurethane foam cannot be recycled and also releaseshazardous toxins while it burns. This new polyester will overcome all thedrawbacks of the PU foam.

Consumers, now a days arebecoming more and more aware of environmental safety, health and hygiene.Hence, health, safety and environmental conditions are the prime considerationsthat drive the Japanese companies into such kind of research and substantialoutputs. Sustainable growth and evolution of a company depends on theactivities of the company to manufacture products that are friendlier with theglobal environment.

References:

http://homeopathicremedies360.com

To read more articles on

To promote your company, product and services via promotional article, followthis link: