Abstract

Wireless communications is now completely pervasive, andalready is used in many guises by people in everyday life. However until now,the information exchanged has been mainly standard electronic forms of standarddata such as text, images, video. More recently, attention has been increasinglyfocused on sensor-based data, which presents rich new areas for applicationsand research, particularly in the area of life-logging applications. Thus,focus must shift to developing new and novel sensor layers to bridge thisinterface between the real world of the body and the digital world ofcommunications. The easiest means to do this is with wearable sensors, but thisin turn raises the issue of comfortable body monitoring systems. If thewearable device is uncomfortable then user compliance will be greatly compromised. At present many conventional sensors are unsuitable for wearable body monitoringdevices, however, in this paper, we present a prototype wearable device which wasused and compared to an established non-wearable method for monitoringbreathing frequency.

Index Termswireless personal communications, body sensor networks, wearablesensors, conducting polymers, personalized healthcare.

I. Introduction

The area of wireless telecommunications has changed dramaticallyover the last few years, and now affects many aspects of modern life. Where once they were aspects ofnovel research, many communication protocols are now being incorporated intoconsumer products such as mobile phones, PDA devices, laptops and PCs, enablinghigh speed connections directly between individuals whenever the service isdemanded [1]. It is believed that many wireless technologies, such as 3G, Wi-Fiand WiMax will be able to coexist to meet any future individual customer needs.

However, accepting that the communication infrastructure iscurrently available, how and when, it is used comes down to the type ofinformation that can be transmitted through this infrastructure. The type of informationthat is to be transmitted must carefully be considered as content and frequencyof transmission will have huge effects on the amount of bandwidth required andalso the power demands of the system. In any type of communication, the qualityof information is paramount. If the selectivity and sensitivity of the data canbe tuned before gathering, less of an emphasis will be placed on data processing resulting in a less complex system. Therefore, technology must focus on maximisingthis sensitivity and selectivity of data gathering, right down to the interfacebetween the source of the information from the real world, and the transmitted,digital data that is logged and displayed by the computer; that is the sensor interface[2].

Sensors, by their nature, sense or generate a detectablesignal to a specific change. The characteristics of a signal generated such as sensitivity, selectivity, and responsetime can all be manipulated to desired limits depending on the objective of theoverall sensing system. For example, if the aim of the sensing system is to monitorgaseous emissions from a landfill site over a number of years, then a robust,low powered, low frequency sampling (< 1Hz) system is required. However, ifthe aim of the system is to monitor the limb movements of a person, then a highfrequency (>20 Hz) sampling system located close to the body would be required.

While it is possible to use non-contact techniques such asmotion capture to track body movements, e.g gait analysis, this type of monitoring yields little information regardingthe vital functions of the body, e.g. ECG, heart rate, or respiration rates.Instead, intimate contact between the body and the sensors is required in orderto pick up this more detailed information. Thus, while it is necessary todevelop robust sensing systems to withstand wear and tear during generaloperation, the physical format of the sensing device, if it is to be maintainthis close body contact, i.e. be worn, it must not compromise the comfort orlimit the activities of the wearer.

Essentially the key-advantage that wearable sensing technologycan offer the user is personal convenience. If a wearable sensor is successful,it will operate without interfering with the daily activity of the user. Theneed for wireless communications is self-evident, as wired systems require highmaintenance and limit the freedom of the wearer, and in so doing hamper theretrieval of a true reflection of the wearers activity. Therefore, the key objectivefor research in this area is to combine functionality (i.e. ability to sense auseful parameter) with ease of integration into clothing, to maintain anagreeable level of comfort for the wearer. However, the issue is to determinewhether the wearability of a sensor will negatively impact on the signal generatedas compared to a more reliable, but un-wearable standard method and whetherthere is a potential use for such a device?

This study aims to demonstrate the performance of a wearable sensor, a conducting polymer modified foam sensor, in a continuous body-monitoring application. In section II a brief explanation of the conventional systems presently used to determine the breathing frequency of an individual is given. This is followed by a brief summary of other current wearable sensors that have been developed for research, highlighting the initial limitations that these sensors have experienced. Section III describes our novel wearable sensors developed and employed for monitoring the breathing frequency of our subject group. Hardware and software requirements of the system are described in section IV, which is then followed by summarizing the integration of these sensors together with the wireless data gathering system to complete the wearable prototype garment. A comparison of the performance of the prototype garment versus the standard method for monitoring the breathing function of a subject group is then presented in section V to ascertain whether the signal from a soft polymer-based sensor can be used in a practical deployment and to determine

II. Concepts in ambulatory monitoring

Wearable sensors as a new technology are slowly beginning to appear in the market place, surfacing first in the areas of sport applications, healthcare, and public safety. However it is predicted that investment will continue in these market segments, with the result that the global market for biophysical monitoring wearable systems is expected to reach 265 million by the end of 2007 [3]. At present, biophysical monitoring systems are predominantly medical devices which are invasive, uncomfortable to wear, or require clinical infrastructure for operation. This is often dictated by the level of precision and quality of signal required for medical analysis, as this can directly influence the clinical outcome of patient. Thus, the percolation of wearable sensors into this medical area will be slow as reliability and stability of testing will require close scrutiny.

Instead though, wearable sensors are becoming increasingly available in the area of non-critical continuous biophysical monitoring [4]. This growth has been spurred on by the demand for contextual information by various audiences; for example for emergency response units [5] and for to athletes who need real-time information regarding their physical status during training sessions. Examples of non-critical continuous monitoring include continuous gait analysis, heart rate monitoring or continuous measuring of respiration rate (breaths per minute or BPM). In this way the user themselves become more educated about their health status and take more responsibility for their medical outcome.

For example a persons breathing frequency or BPM can be linked to a number of physiological responses such as activity rate, stress, emotional activity or indeed medical conditions such as sleep apnea [6]. Respiratory rates of 15-20 BPM are representative of resting breathing frequency in an adult population free from respiratory disease. Determination of the respiration rate of an individual during exercise can yield information regarding the health status of the individual and determine whether changes to their activity need to happen to maximize their performance.

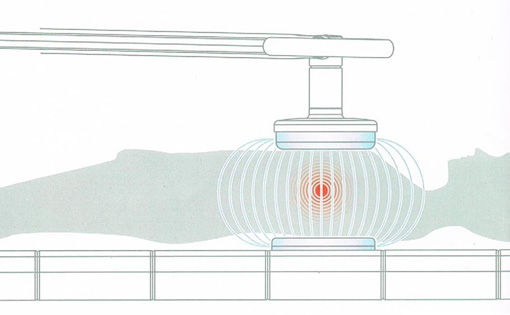

Respiration rates can be measured in non-invasive ways, using a pneumotachograph, which is used to record the rate of airflow to and from the lungs. This clinical apparatus requires the user to wear a head-mounted breathing tube. The advantage of this type of sensor is that it can yield detailed information on volume and direction of breath. However, these devices are often unwieldy, and are not be suitable for continuously monitor the status of the user. Another clinical device, the plethysmograph, can also be used to record breathing rates by measuring volume changes around the chest to determine lung capacity. However, though both of these methods are well established, they employ hard-wired devices that require interconnections to external equipment and cannot be used outside a specialized clinical environment. Thus, a comfortably worn continuously monitoring sensing device that can be operated by non-specialists, to provide information, for example, about breathing rates on a continuous basis would be very welcome.

A. Disappearing wearable sensors

Several approaches to develop wearable monitoring systems have employed traditional technologies such as accelerometers, gyroscopes, strain gauges [7], piezoelectric materials [8] , fibre-optics [9] and pressure sensors [10], strapping the sensors to the body, adhering them to the skin, or integrating them into skin-tight garments [11, 12]. While this approach can offer precise monitoring of certain parameters, it requires the user to compromise their physical comfort in order to accommodate the device. In many applications this is an important issue, because if the device is designed to record the normal activities of a person, then the activity of attaching the device in itself can eschew the persons routine by introducing this new activity of attaching the sensor. Also if the person cannot get immediate feedback that rewards them for using the device it is highly likely that this activity will fade out of the normal routine, in which case, no record of the person will be generated, rendering the whole study of that person useless. Clearly, it would be better if the device were to disappear into the users environment where it would continuously record the information from the user.

This sensor integration can be achieved through various methods, but in perhaps the most elegant approach is to functionalise textiles and fabrics, such that the material itself manifests sensing capabilities. Textilebased sensors offer a solution for discomfort by retaining the characteristics of the textile, i.e. comfort and wearability, while also functioning as a sensor and providing information to the user. Thus, they are sometimes referred to as smart textiles. The characteristics of a textile-based sensor are flexibility, surface area, washability, stretch and texture. As it will be necessary to bridge these sensors to digital communication hardware, these sensors must also include the properties required for electronic devices including durability, low power consumption, and ease of connection into a circuit. Unfortunately not all traditional sensor materials are suitable for integration into textiles. For example, metallic components, designed to function in rigid environments do not make for comfortable garments and will soon break in such a high-flex environment.

Conducting electroactive polymers (CEPs) may offer a solution to this problem. CEPs such as polypyrrole (PPy), polyaniline and polythiophene constitute a class of polymeric materials which are inherently able to conduct charge through their conjugated polymeric structure. PPy, in particular, has attracted much interest, as it is easily prepared in a number a number of formats; films, powders or composites. It has a relatively high conductivity and good air stability in its conducting state. When applied as a coating to soft flexible substrates, PPy has little effect on the mechanical properties of the substrate, but renders the entire structure electroactive. Therefore, it is possible to make a material, such as a textile conducting material while retaining the soft physical characteristics of the material.

PPy-coated textiles have been used in a number of previous wearable sensing applications [13-16]. These applications employed knitted textiles; where the materials ability to sense stretch corresponded to increased conductivity through the material. Thus, the material itself becomes the sensor.

III. Prototype garment

In the paper presented here, a pressure sensitive foambased PPy sensor was used as a wearable device. The foam-based PPy sensor was constructed by depositing layers of PPy onto the polyurethane (PU) substrate. This process is described in detail in [17]. Samples of the coated-foam material were cut to approximate sizes of 2cm x 2 cm x 1.5 cm and were sewn into a pocket on the t-shirt test garment at the rib cage region of the subject, with two wire leads attached to the sensor. A nonextensile gross-grain ribbon strap was positioned around the thoracic region of the subject, on top of the sensor, to secure the mote and maximise the response from the sensor.

Due to the movement (expansion and collapse) of the chest wall during respiration, the foam was repeatedly compress and then allowed to relax to its original shape. This resulted in a signal that modulated between a maximum and minimum conductivity measurement which could be converted to a voltage difference across the sensor. This changing voltage signal was fed into the ADC ports on the data acquisition board.

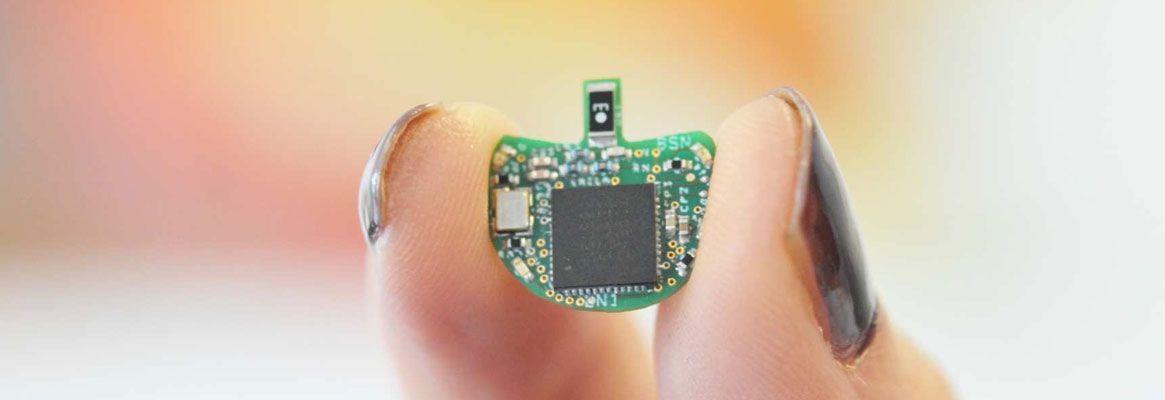

A small lightweight Mica2Dot (MPR5x0) was used as the wearable sensor mote and a MICA2 series (MPR4x0) mote, connected directly to a laptop through the RS232 port was used as the basestation. The Mica2Dot mote was approximately the size of a 2 Euro coin and thus could easily be worn by an individual during testing. Both motes, shown in Figure 1, used the low power 10- bit microcontroller, ATMega 128L and the Chipcon CC1000 FSK-modulated radio transceiver. TinyOS was used on the motes and an Oscope Programme, developed by Intel, was used to display and record the data.

Retrieval of information from the foam sensors was facilitated by these Crossbow MICA2 wireless mote platforms, at a packet reception rate of 20 Hz, enabling the data to be continuously logged and displayed in realtime to give feedback to the user and tester alike. The indoor range of the motes is 30m [18], however, non of our subjects moved more than 10m away from the basestation, therefore this limitation was not determined during this testing. The finished prototype is shown in Figure 2.

IV. Methodology

The purpose of this study was to determine the performance of the t-shirt prototype in detecting the number of breath performed by a subject in comparison to a standard non-wearable method.

In order to determine this, a 20 minute breathing programme was devised to demonstrate a number of different breathing styles. This programme was performed with 10 randomly selected male subjects, aged 23 3 years. The programme was broken into 5 oneminute stages each representing a different breathing pattern. To initiate the test subjects inhaled deeply and held their breath for 10 seconds before exhaling. Subjects, then, proceeded to breathe normally for 1 minute. They were then instructed to breathe at a paced rate of 10 breaths per minute signalled by the respiratory rate (RR) value on the standard clinical breathing monitor for 1 minute. Stage three required the subjects to breathe deeply for 1 minute, while stage four required them to breathe at a rate corresponding to approximately 40 breaths per minute as indicated by respiratory rate value for 1 minute. Finally, for stage five, the subjects were instructed to take shallow inspirations with minimal displacement of the chest for 1 minute.

For all tests, the subject was required to wear the prototype t-shirt and the necessary apparel for the standard clinical breathing monitor (Vmax 229 Metabolic System, SensorMedics), which included a noseclip, mouthpiece and supporting head brace which are required when performing standard measurements of breathing with the metabolic system. The information recorded by the metabolic system was gathered by PC associated with the system. The sensor in the Vmax metabolic system was designed to register the starting time of each inhalation, which triggered a timer to determine the length and thus rate of breathing. These starting times were used as markers for each breath, which were manually counted per stage.

Analysis of the data from the fo am sensor was performed using OriginPro Software v7.5 (Silverdale Scientific, UK) to pick out and count the peaks recorded by the sensor. Comparison of the number of breaths detected by the standard and wearable system was then performed to assess the degree of correlation between the two data sets.

V. Results & discussion

The five breathing patterns used in this study were selected to represent a variety of breathing styles that a person may perform during daily activities. The normal breathing rates for each individual are expected to differ the greatest across the subject group, while deep breathing and hyperventilation represented the extreme limits to breathing without causing undue discomfort to the subjects. Shallow breathing was also investigated as it may be suggestive of stress to the individual. As can in seen in Figure 3 the response detected by the foam sensor for this subject (subject #3) was clearly able to distinguish between the style of breathing deeply and hyperventilating. The sensor could register both the changes in frequency and depth of movement that occurred during testing.

Once each subject has performed the 5 different breathing styles, the peak counts (number of breaths as registered by the foam sensor) and the number of breaths recorded by the standard metabolic machine were counted and compared. The average breath count across the subject group for each breathing style is shown in Figure 4, where it was observed that there was no significant difference between the two datasets [16].

It can be observed that the standard deviation of breaths counted for both hyperventilation and shallow breathing were the largest for both testing systems. This is because both of these styles of breathing are very much unique to each individual subject, therefore the standard deviation is representative of the inherent differences between each person. However it is noted that the sizes of these standard deviations for each breathing style were similar, thus it can be seen that the prototype garment performed in a very similar manner to the standard measurement system. This high correlation between both datasets indicates that the signal generated by the foam sensor is a true reflection of the breathing activity of the wearer. It was noted also during testing that the prototype garment configuration employed did not appear to impede the subjects movements during testing. Also the wireless connection to the Mica Motes did not have any effect on the accuracy of the response of the foam sensor.

VI. Conclusion

The results obtained by this study show that is it possible to develop a simple wearable system to monitor the breathing frequency of a number of individuals, without having to compromise the users physical activity or general comfort. Also integration of this sensor into a wireless platform implied that the issue of interconnecting wires could be avoided releasing the individual to move in space in a way they are normally accustomed to. The material itself is low cost, and easily integrated into garments. Thus, this approach successfully combines the benefits of soft textile-like sensors with the freedom of wireless sensors. Our primary objective was to develop a successful wearable and wirelessly integrated body monitoring system. These results confirm a material, PPy-PU foam, can be comfortable to wear but also generate accurate and meaningful results.

Importantly, the sensor maintains the attractive structural properties of foam, consistent with the objectives of wearability, washability, and comfort in a smart garment.

It is our intent to build on this vision of delivering rugged and reliable body sensor networks that are able to gather information of the same quality and quantity that can be currently gathered from laboratory based reference sensing systems, and to generate more complex body sensor networks whereby information from multiple positions on the body can be brought together through the use of simple wearable sensors and a wireless communication platform

VII. Acknowledgements

This material is based on work supported by Science Foundation Ireland under Grant No. 03/IN.3/1361. We would also like to acknowledge the support of the Irish Research Council for Science Engineering and Technology. Thanks also to the subjects who participated in this study.

VIII. References

1) Intel Corporation. Broadband

Wireless Technologies. [website] 2006 [cited 2006 27 NOV 06];

Website]. Available from:

http://www.intel.com/netcomms/bbw/index.htm

2) D. Diamond, Internet-scale sensing. Analytical Chemistry, 2004. 76(15): p. 278A-286A.

3) Venture Development Corporation, Wearable Systems: Global Market Demand Analysis. Vol III: Infotainment Solutions. 2005.

4) P.F. Binkley, W. Frontera, D.G. Standaert, and J. Stein, Predicting the potential of wearable technology - Physicians share their vision of future clinical applications of wearable technology. Ieee Engineering in Medicine and Biology Magazine, 2003. 22(3): p. 23-27.

5) F.H. Wilhelm, W.T. Roth, and M.A. Sackner, The lifeShirt. An advanced system for ambulatory measurement of respiratory and cardiac function. Behav Modif, 2003. 27(5): p. 671-91.

6) M. Arzt, T. Young, L. Finn, J.B. Skatrud, and T.D. Bradley, Association of sleep-disordered breathing and the occurrence of stroke. Am J Respir Crit Care Med, 2005. 172(11): p. 1447- 51.

7) G.M. Spinks, G.G. Wallace, L. Liu, and D. Zhou, Conducting polymers electromechanical actuators and strain sensors. Macromolecular Symposia, 2003. 192: p. 161-169.

8) R. Ishida, Y. Yonezawa, H. Maki, H. Ogawa, I. Ninomiya, K. Sada, S. Hamada, A.W. Hahn, and W.M. Caldwell, A wearable, mobile phonebased respiration monitoring system for sleep apnea syndrome detection. Biomed Sci Instrum, 2005. 41: p. 289-93.

9) M.L. Davies, C.J. Hamilton, S.M. Murphy, and B.J. Tighe, Polymer Membranes in Clinical Sensor Applications .1. An Overview of Membrane-Function. Biomaterials, 1992. 13(14): p. 971-978.

10) T. Someya, T. Sekitani, S. Iba, Y. Kato, H. Kawaguchi, and T. Sakurai, A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. Proceedings of the National Academy of Sciences of the United States of America, 2004. 101(27): p. 9966-9970.

11) E.H. Chi, Introducing wearable force sensors in martial arts. Pervasive Computing, IEEE, 2005. 4(3): p. 47-53.

12) T. Misawa, Y. Kutsumi, H. Tada, S.S. Kim, T. Nakai, S. Miyabo, T. Hamada, I. Arai, and T. Suzuki, Noncontact and noninvasive microwave biological measurements. J Cardiol, 1990. 20(1): p. 209-16.

13) F. Lorussi, W. Rocchia, E.P. Scilingo, A. Tognetti, and D. De Rossi, Wearable, redundant fabric-based sensor arrays for reconstruction of body segment posture. Ieee Sensors Journal, 2004. 4(6): p. 807-818.

14) B.J. Munro, J.R. Steele, T.E. Campbell, and G.G. Wallace, Wearable textile biofeedback systems: are they too intelligent for the wearer? Stud Health Technol Inform, 2004. 108: p. 271- 7.

15) J.R. Steele, G.G. Wallace, and B.J. Munro, The intelligent knee sleeve: A valid and reliable device to combat ACL injuries. Journal of Science and Medicine in Sport, 2002. 5(4, Supplement 1): p. 10-10.

16) S. Brady, B. Carson, D. O'Gorman, N. Moyna, and D. Diamond. Combining wireless with wearable technology for the development of onbody networks. in Wearable and Implantable Body Sensor Networks. 2006. Boston: IEEE. 2006IEEE

17) S. Brady, D. Diamond, and K.T. Lau, Inherently conducting polymer modified polyurethane smart foam for pressure sensing. Sensors and Actuators a-Physical, 2005. 119(2): p. 398-404.

18) Crossbow. Crossbow

MICA2COT series. 2005 [cited 2005 October, 2005]; Available from:

http://www.xbow.com/Products/Product_pdf_files/Wireless_pdf/MOTE-KIT_Datasheet.pdf

About the Authors:

Sarah Brady and Dermot Diamond are associated with Adaptive

Information Cluster, NCSR, Dublin City University, Dublin, Ireland.

Brian Carson, Donal OGorman and Niall Moyna are associated with School for Human Health and Human Performance, Dublin City University, Dublin.

This paper is based on Combining wireless with wearable technology for the development of on-body networks, by S. Brady, B. Carson , D. OGorman., N. Moyna and D. Diamond which appeared in the Proceedings of the IEEE International Conference on Wearable and Implantable Body Sensor Networks 2006, Boston, USA, April 2006. 2006 IEEE.

Originally published at:

http://www.academypublisher.com/jcm/vol02/no05/jcm02050106.pdf

To read more articles on Textile, Industry, Technical Textile, Dyes & Chemicals, Machinery, Fashion, Apparel, Technology, Retail, Leather, Footwear & Jewellery, Software and General please visit http://articles.fibre2fashion.com

To promote your company, product and services via promotional article, follow

this link: http://www.fibre2fashion.com/services/article-writing-service/content-promotion-services.asp