By: Dr. Uwe Vohrer and Dr. Christian Oehr

Due to increasing requirements on the finishing of textilefabrics, increasing use of technical textiles with synthetic fibers, as well asthe market and society demand for textiles that have been processed by environmentallysound methods, new innovative production techniques are demanded. In thisfield, the plasma technology shows distinct advantages because it isenvironmentally friendly, and even surface properties of inert materials can bechanged easily.

Plasma technology can be used not only for textilefinishing, but also for the optimisation of textile machines, for example, withhard coatings.

It has been known for at least 60 years that plasma couldeffect desirable changes in the surface properties of materials. However, thepractical application of plasma required the development of commerciallyavailable, reliable, and large plasma systems. Such systems are now available(mostly in research laboratories) and the application of plasma to industrial problemshas been increasing rapidly for the past 10 years.

Definition of plasma

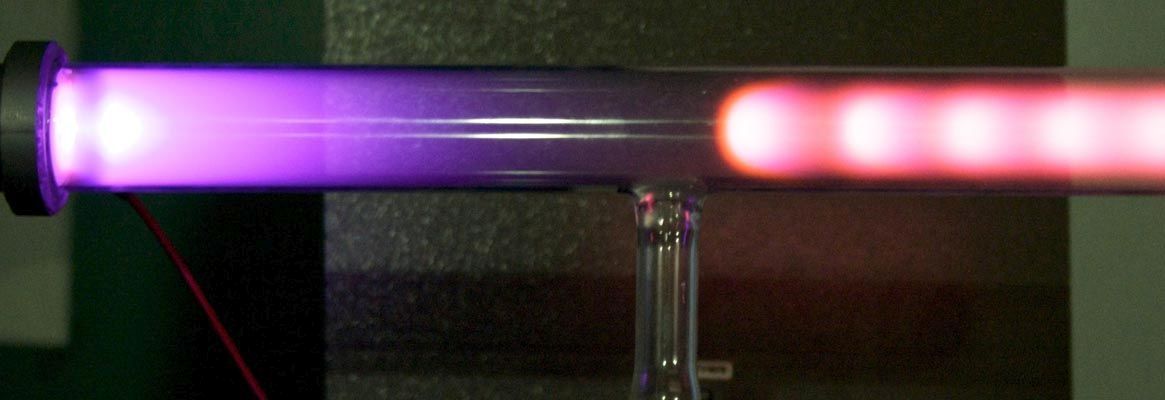

The physical definition of "plasma" (glow-discharge)is an ionised gas with an essentially equal density of positive and negativecharges. It can exist over an extremely wide range of temperature and pressure.The solar corona, a lightening bolt, a flame and a "neon" sign areall examples of plasma. For the purposes of textile modification the lowpressure (0, 01 to 1 mbar) plasma, such as found in the "neon" signor fluorescent lightbulb are used. In the above mentioned applications thedesired result is to produce light. However, for the plasma treatment ofpolymeric substrates, the extremely energetic chemical environment of theplasma is utilised.

Originallypublished in New Cloth Market: October 2009