Shapememory is the ability of a material to remember its original shape, thematerial deformed into a temporary shape and returns to its original shape byexternal stimuli. The first materials known to have these properties were shapememory metal alloys (SMAs) which have been developed in 1960s.

ShapeMemory Polymers (SMPs) are one type of shape memory materials defined aspolymeric materials with the ability to sense and respond to external stimuliin a predetermined shape, which were firstly developed in France andcommercialized in Japan in 1984.

Polymerssuch as polynorbornene, trans-polyisorprene, styrene-butadiene copolymer,crystalline polyethylene, some block copolymer, ethylene-vinyl acetatecopolymer and segmented polyurethane' etc., have been discovered with shapememory effect.

Comparedwith shape memory alloys, SMPs have better potentiality for textile andclothing, and related products: in case of SMAs, mechanical properties can beadjusted only within a limited range and the maximum deformation that canundergo is about 8%. On the other hand, shape memory polymers (SMPs) have easyshaping, high shape stability, and adjustable transition temperature. Shapememory polyurethane (SMPU) is a class of polyurethane that is different fromconventional polyurethane in that these have segmented structure and a widerange of glass transition temperature (Tg). If a SMPU is cooled from above Tgto a temperature below Tg, in presence of a mechanical load, and after removalof load, significant deformations anywhere in the range of 10-200% get lockedinto the polymer.

Thesedeformations and the original shape are all recoverable when the polymer isheated back beyond Tg. Both the shape memory effect and the elasticity memorysystem effect of shape memory polymers make them a useful candidate for today'sintelligent material systems and structures.

TheMechanism of SMPU

Shapememory may be triggered by heat, light, electricity and other stimuli. Theshape memory polyurethanes to be discussed in this paper are thermo sensitiveSMPUs. SMPUs are composed of incompatible hard and soft segments that demix ona molecular level to form a micro phase separated structure. The hard microphase is a hard segment-rich micro domain, which is generally semicrystallineand imparts stiffness and reinforces to the material. The soft segment-richmicro phase, which is responsible for the elastic behaviour of polyurethane's,is usually amorphous with a glass transition temperature (Tg) below roomtemperature. A large, reversible change in elastic modulus across the Tg makesshape change and shape retention possibility.

At temperature above the glass transition temperature (Tg), the polymer achieves a rubbery elastic state where it can be easily deformed without stress relaxation by applying external forces over a time-frame t<<t, where it's a characteristic relaxation time. When the material is cooled below its Tg, the deformation is fixed and the deformed shape remains stable. The pre deformation shape can be easily recovered by reheating the material to a temperature higher than the Tg55. Therefore; admirable shape-memory behavior requires a sharp transition from glassy state to rubbery state, a long relaxation time, and a high ratio of glassy modulus to rubbery modulus.

The micro morphology of SMPU strongly affects its mechanical properties. There are many factors, which can influence this morphology SMPUs: chemical structure, composition, and sequence-length distribution of the hard segments, overall molecular weight and its distribution.

The ordinary PU and SMPU

The properties of ordinary polyurethane (e.g., from 1, 6-hexane diisocyanate and 1,4-butane diol) are similar to polyamides. It is composed of two starting material33, such as:

a) diisocyanate and

b) Either short chain glycol or long chain polyethers or polyester glycol.

The PU made by short chain glycol and diisocyanate has mUltiple hydrogen bonding35 between - NH- and -OC- groups, which result in high hardness and strength and low degree of solubility.

On the other hand PU obtained by reaction of long chain, non-crystalline, unbranched, OH-functional polyethers or polyesters (which do not contain free or low molecular weight glycols) with stoichiometric amounts of diisocyanates contain about 4 to 7% urethane groups 34. The intermolecular forces for polyethers and polyesters PU are weak van der Waals force, as result, hardness and strength are comparatively low and the product exhibit rubber-like properties. Both types of products have only one phase. The technical importance of ordinary PU is cross linked hard products (PU rigid foams, non-textile coatings).

Segmented polyurethanes can show shape-memory properties. Shape memory PU are composed of at three basic starting materials, these are a) long chain polyether or polyester polyol, b) diisocyanate and c) glycol or diamine (chain extender). Diisocyanate and chain extender are hard segment, on the other hand long chain polyol is soft segment. These types of polyurethane are characterized by a segmented structure (block copolymer structure) and the morphology depends on chemical composition and the length of the segment (block). The shape memory polyurethane has micro phase separated structure due to the thermodynamic incompatibility between the hard and soft segment. Hard segments can bind themselves via hydrogen bonding and crystallization, making the PU very solid below melting temperature.

Reversible phase transformation of soft segment is reported to be responsible for the shape memory effect. The shape memory effect can be controlled via molecular weight of soft segment, mole ration between hard and soft segment, and polymerization process. The typical textile applications of shape memory polymers are as fibre and coating etc.

The Properties of SMPU

Shape memory effect Ordinary polyurethane cannot completely restore their residual inelastic deformation upon heating. In contrast, SMPUs can recover all the residual plastic deformation up to 400% through a micro-Brownian movement triggered by heating them 10-20C above their glass transition temperature (Tg).

Furthermore mechanisms of shape memory affect, structure, and properties of such polymers have been studied. The shape memory effect of segmented polyurethane is due to the network structure formed by hard and soft block. The hard blocks are formed by the reaction of diisocyanate with low molecular weight glycol, or diamine (chain extender). The hard blocks constitute about 30-50% by weight of the total polymer.

On the other hand, soft segments are formed by polyol (oligomer). The microphase separation of these two dissimilar blocks produces regions of hard blocks concentration (domains) which act as cross-link points for the soft blocks. The network structure can be easily deformed above glass transition temperature (Tg) to give a temporary shape, the original shape can be recover when the material heat above the glass transition temperature.

Permeability

Temperature dependency of water vapour permeability is an important factor to be considered for the effective utilization of this type of smart materials. The shape memory effect can be applied to the areas like smart fabrics that can control moisture permeability.

The fabrics coated or laminated with SMPU should have higher water vapour permeability at higher temperature and low water vaoour permeability at lower temperature.

Other Properties:

When SMPU changed from glassy state to rubbery state, Young's modulus, tensile and elastic properties would vary greatly, which would be useful for garments. For example, when the SMPU based garments would wash at higher temperature or worn at body temperature, it could recover to the original state (wrinkle free). Other properties, such as wrinkle free, permeability and absorbability can also be considered with SMPU.

Some Applications of Shape Memory Polyurethane (SMPU) in Textile

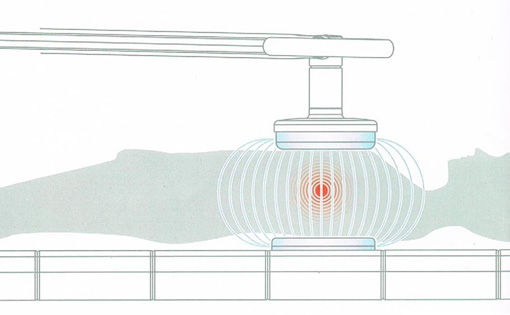

Brownian motion occurs when the temperature rises above a predetermined activation point.

As a result of this motion, micro-pores are created in the SMPU membrane, which allows water vapor and body heat to escape. Because permeability increases as the temperature rises, the membrane is able to respond intelligently to changes in the wearer's body and environment temperature. When the temperature is low, the membrane acts to reduce permeability and prevent the heat and sweat to pass through it. This helps to retain body heat.

This ''flexible barrier function" enables the garment to intelligently adjust its insulating properties in response to temperature changes, assuring excellent moisture management properties and increases comfort. So when the shape memory polyurethane is activated in garments, confers greater versatility in the protection the garment provides against extremes of heat or cold. For clothing applications, the reversible temperatures for the shape memory effect to be triggered should be near body temperature.

The SMPU can be used with textiles. They can be laminated, coated, filmed, foamed and even straight converted to fibres. The following are the several applications that were reported in the literature:

When shape memory polyurethane laminated to a fabric, a smart fabric (waterproof, windproof, and breathable) is formed. It is also possible to coat SMPU on a fabric such that its permeability changes as the wearer's environment and body temperature change to form an ideal combination of thermal insulation and vapor permeability for army clothing.

When the body temperature is low, the fabric remains less permeable and keeps the body heat. When the body is in a sweat condition, it allows the water vapour to escape into the air because its moisture permeability becomes very high with increasing body temperature. This releases heat from the apparel. Since the fabric is waterproof, the apparel made with coated or laminated SMPU fabric can be used regardless of weather. Some application of shape memory polyurethane in textile including the followings:

- Thermal Protective Clothing

- Sportswear

- Leisurewear

- Underwear

- Outerwear

- Gloves

- Socks

- Shape memory fibres

- Smart fabric

Conclusion:

There are many reports about shape memory polymers, although these polymers have been proposed for a number of uses, their textile applications have been limited; due the reversible temperatures for the shape memory effect to be triggered is higher than body temperature. Polyurethane - based shape memory polymers with a wide range of glass transition temperatures drawn interest in the textile field. The study of SMPU is still limited. Their shape memory mechanism, the relation between structure and effect, especially their application to textiles and garments still has potentiality to develop.

This article was originally published in the August issue of the magazine, New Cloth Market The complete Textile magazine from textile technologists. It was written by Subrata Mondal, Jinlian Hu, Zhuohong Yang, Van Liu and Yau-shan Szeto who are professor at Institute of Textiles & Clothing, The Hong Kong Polytechnic Univ., Hung Hom, Kowloon, Hong Kong Wuhan Institute of Science and Technology, China