Abstract

Polypyrrole chemically synthesized on PET gives riseto textiles with a high electric conductivity, suitable for severalapplications from antistatics to electromagnetic interference shieldingdevices. Here, we discuss investigations on thermal electric performances ofthe polypyrrole coated PET in a wide range of temperatures above roomtemperature. The Seebeck coefficient turns out to be comparable with that ofmetal thermocouple materials. Since polypyrrole shows extremely low thermaldiffusivities regardless of the electrical conductivity, the low thermalconductivity gives significant advantage to the thermoelectric figure-of-merit ZT,comparable with that of some traditional inorganic thermoelectric materials.The heat generation is also investigated for possible heating textile devices.

Keywords: conductive polymer, polypyrrole, thermoelectricmaterials

About the Authors:

Toread more articles on

To promote your company, product and services via promotional article, followthis link:

The molar ratio of polymerisation catalyst, iron (III) nitrate, to monomer (pyrrole) equal to 2.3 mol/mol was used for all reactions. The macroscopic texture of this Contex-like fabric is shown in Fig. 1, a net useful for application in heating systems, as we shall demonstrate in following discussion. In Fig.1, a commercial metallized fabric (Leno Ni/Ag coated Nylon) is shown for comparison. Simultaneous in-situ polymerisation and deposition of conductive polypyrrole leads to production of conductive, smooth and uniform coating with thickness under 1 μm, according to transmission electronic microscope measurements (see Fig.2 and 3). The electrical DC surface resistance was measured by using a four-in-line point probe in combination with computerized Loresta-AP meter from Mitsubishi Petrochemical Co., LTD. Surface resistivity at room temperature of conductive fabrics. The PPy/PET fabric has a DC surface resistivity of 306.0 / sq and the Leno of 0.22 / sq. As observed in Ref.11, it is possible a formation of insoluble polymers in the bulk solution and on the surface of the substrate simultaneously. The bulk polymerization produces dendritic polymer particles in the solution and the surface polymerization forms a polymer film on the substrate surface. Some of the bulk polymer precipitates on the surface of the substrate and then the SEM analysis shows these particles on the fibers.

Thermal Electric Effects:

Few researches on organic materials for thermoelectric applications have been reported, probably because of their unattractive electronic transporting characters. But recently electrically conducting organic polymers with aromatic structures have attracted a great attention because of electrical properties and considerable thermal stability. Among them, polyaniline and polypyrole are well studied due to feasible background for wide application to electronic devices and sensors [12, 13, 14]. The experimental results of systematic investigations on thermoelectric performances of polyaniline and polypyrole films in a wide temperature range above room temperature have been reported.

Supposing for polymeric compounds a low thermal conductivity, we can obtain significant advantage of the thermoelectric figure-of-merit.

Let us remember that figure-of-merit is defined as ZT S 2T, where S, , and T are Seebeck coefficient, electric conductivity, thermal conductivity, and absolute temperature respectively. The value of ZT for polypyrrole is comparable with that of some traditional inorganic thermoelectric materials, for instance FeSi2 [7]: in polypyrrole films, the maximum value is 10−2 at 423K [15]. We investigated the behavior of resistivity as a function of temperature. Starting from room temperature, the resistance of a PPy/PET sample placed in a thermostage was checked till a temperature of 70C. The resistance behavior with temperature is typical of a semiconductor with the resistance decreasing linearly as the temperature increases. At room temperature, the resistance was of 172 in a sample with a length of 4 cm, composed by 10 yarns, each yarn with a diameter of 0.05 cm. At 70C, the resistance of the sample was of 145 . Assuming a thickness in polypyrrole coating of around 1 μm. The electrical conductivity σ turns out of a 104 W −1m−1. This estimation is in good agreement with the value of 1.7 104 −1m−1, given in Ref.16.

Thermoelectric Seebeck coefficient (S) and its temperature dependence were determined by connecting a stripe of PPy/PET fabric 0.5cm wide with a copper wire. The two materials are electrically connected by the pressure of a very small silver clip, insulated from the junction. The hot junction was placed in the thermostage with a reference Chromel-Alumel thermocouple and the cold junction between the PPy/PET stripe and copper was thermally anchored at room temperature (26 C). The same anchoring was used for the cold junction of the Chromel-Alumel thermocouple (a diagram of the experimental set-up in Fig.4). Variations in monitored room temperatures during measurements were negligible (around 5%). In Figure 5, the behavior of the electro-motive force measured for two such PPy/Copper thermocouples is given as a function of temperature difference T between the actual hot junction temperature and the room temperature. Assuming a value of Copper e.m.f. vs. Platinum of 0.0076 mV/C [17], we can estimate a value of 0.0133 mV/C for the PPy vs. Platinum e.m.f. and positive. To obtain the figure of merit (ZT), we estimate the PPy thermal conductivity in the following manner. Thermal diffusivity of polypyrrole films was measured by a laser flash method in Ref. [18]. Polypyrrole films exhibit extremely low thermal diffusivity of 1.310−2 cm2s−1 at room temperature. The very low thermal diffusivity of polypyrrole films is originated in the lattice structure, in particular from a dominant amorphous character of the chain structure. An amorphous structure strongly reduces the thermal phonon transport, because strong phonon Scattering mechanisms appear [19, 20]. Specific heat capacity of the polypyrole film is 0.4 J g −1K −1, which is higher than those of inorganic materials but still in the range of those of organic polymers, with a positive temperature dependence [18]. The thermal conductivity of polypyrrole film turns out to be 0.2 Wm−1K−1. This low thermal conductivity is at least in one order of magnitude lower than that of the best inorganic thermoelectric materials. With the estimates s = 104 W −1m−1, k = 0.2Wm−1K −1, T = 300K, our measurements on PPy give ZT = 310−3 in agreement with data on polypyrrole films [15].

The Seebeck electromotive force of Leno Ni/Ag coated Nylon connected with Cu was also measured and the behavior is shown in Fig. 5 (curve b). The same figure shows that a thermocouple built with Ni/Ag/Nylon and PPy/PET can give the higher electromotive force (curve a). We have also prepared a thermocouple with PPy/PET and a yarn composed of commercial carbon fibers (curve c). As shown by the measurements here

reported, PPy coating can be successfully used with other conductive yarns, for instance Copper, Ni/Ag coated yarns or carbon fibers, obtaining stable textile thermopiles, providing significant thermo powers. Seebeck effect of PPy with Aluminum is reported in Ref. [21]. Contex, or other polypyrrole coated textiles, can then represent a valid solution to the problem of exhausted heat, generated from engines and in power plants, to avoid environment thermal pollution. A challenging strategy for textile industry can then be development of new textiles for a partial recovers of heat in electric energy.

Heat Generation:

An adjustable Variac power supply was used to generate an AC current/voltage over the fabric. Voltage and current were monitored by Keithley voltmeter and amperometer. A square shape fabric (6 cm6 cm) was positioned between two pressed electric contacts (a diagram of the arrangement in Fig.7). The temperature rise was measured using an Omega infrared thermometer, placed to control the center of the sample. In Fig.8, the behavior of the temperature as a function of the current is given, with the rise of the voltage. According to the power law, the maximum theoretical power achieved from the fabrics is: P V I, where P is the power developed and V, I the voltage and current. The AC current frequency is 50 Hz. In Fig.9, the power and the impedance as a function of current are shown. In Ref.10, the power density per unit area is assumed to be: 2 SP V 2 / R l, where RS is the surface resistance and l the size of the sample. Our highest value is 370 W / m2 in agreement with the value obtained in Ref.10.

As the studies demonstrate, a Seebeck effects can be achieved by using a PPy conducting coating a PET fabric. According to the Kelvin relation between the Seebeck S and the Peltier P coefficients, P = S T, we can also imagine application in cooling devices of polypyrrole coated fabrics. In fact, the effect is strongly dependent on the design of the cooling cell and in the number of junctions utilized in it. With the PPy coated PET fabric, it is possible to easily make heating fabrics. Since the coating with polypyrrole is possible on many different fibers [22], the potential applications of polypyrrole in the building of heating pads are relevant. We suggest that the PPy-coated fabric used in this study may be practically useful for many applications, including flexible, portable surface-heating elements for medical or other applications.

References:

1. J. Edenbaum editor, Plastics Additives and Modifiers Handbook, Van Nostrand Reinhold, New York 1992.

2. J. Avloni, M. Ouyang, L. Florio, A.R. Henn, A. Sparavigna, Journal of Thermoplastic Composite Materials 20(3), 241 (2007)

3. A.R. Henn, R.M. Cribb, Modelling the shielding effectiveness of metallized fabrics, Interference Technology Engineering Master (ITEM) Update, p. 49-57 (1993)

4. C.K. Chiang, C.R. Fincher, Y.W. Park, A. J. Heeger, H. Shirakawa, E.J. Louis, S.C. Gau, and A.G. MacDiarmid, Phys. Rev. Lett. 39, 1098 (1997)

5. A.G. MacDiarmid, Synthetic Metals 84, 27 (1997)

6. Y.Cao, P. Smith and A.J. Heeger, Synthetic Metals 55, 3614 (1993)

7. Milliken and Co., http://www.milliken.com

8. A.F. Ioffe, Semiconductor Thermoelements and Thermoelectric Cooling, Infosearch, London 1957.

9. H.H. Kuhn, A. D. Child, Handbook of Conducting Polymers, Marcel Dekker, New York, 1998, pp.993-1013.

10. H.H. Kuhn, A. D. Child, W.C. Kimbrell, Toward real applications of conductive polymers, Synthetic Metals 71, 2139 (1995)

11. E. Hakansson, A. Kaynak, T. Lin, S. Nahavandi, T. Jones and E. Hu, Synthetic Metals 144(1), 21 (2004)

12. D. Kumar and R.C. Sharma, European Polymer Journal 34, 1053 (1998)

13. D. Braun, Materials Today 5, 32 (2002)

14. J.V. Hatfield, P. Neaves, K. Persaud and P. Travers, Sensors and actuators B 18-19, 221 (1994)

15. Hu Yan, T. Ishida, and Naoki Toshima, XX International Conference on Thermoelectrics, Proceedings ICT 2001, p. 310

16. A.R. Henn, Calculating the surface resistivity of conductive fabrics, Interference Technology Engineering Master (ITEM) Update, 1996, p. 66-72.

17. D.E. Gray, American institute of physics handbook, McGraw- Hill , New York 1963

18. Hu Yan, N. Sada and N. Toshima, J. of Thermal Analysis and Calorimetry 69, 881 (1992)

19. M.Omini and A.Sparavigna, Phys. Rev. B 61, 6677 (2000)

20. A. Sparavigna, M. Omini, A. Pasquarelli and A. Strigazzi, Int. J Thermophys. 13, 351(1992)

21. Eric Hu, Akif Kaynak, Yuncang Li, Synthetic metals 150, 139 (2005)

22. D.T. Seshadri and N.V. Bhat, Synthesis and properties of cotton fabrics modified with polypyrrole, SenI Gakkaishi 61(4), 103 (2005)

Figure Captions:

Fig.1 Polypyrrole coated PET net and the Leno Ni/Ag coated nylon fabric. The image sizes are 4.3cm5cm.

Fig.2 Scanning electron microscope SEM images of the samples with polypyrrole coated fibers. The dust is due to polymer particles in solution, deposited on the net.

Fig.3 SEM images of PPy coated fibers.

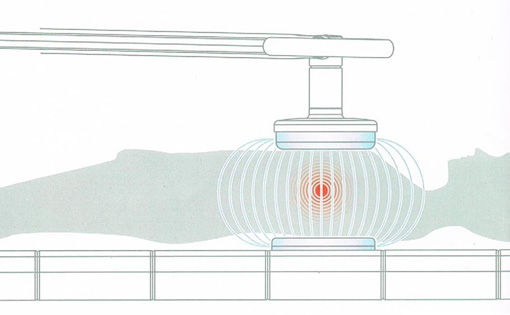

Fig.4 The diagram of the experimental setup for measuring the Seebeck effect. The electromotive force of two thermocouples are compared: a thermocouple is used as a reference to determine the temperature in the thermostage, the other to determine the unknown electromotive force of the material.

Fig. 5 Electromotive force measured for a PPy-PET/Copper thermocouple as a function of the temperature difference T between the actual hot junction temperature and the room temperature.

Fig. 6 Electromotive force measured for Ni/Ag/Nylon/Contex (a), for Ni/Ag/Nylon/Copper (b), and for PPy/PET/Carbon Fibers as a function of the temperature difference T between the actual hot junction temperature and cold junction at room temperature.

Fig.7 The diagram of the experimental set-up for measuring the heating effect of a textile. Current and voltage across the sample must be monitored.

Fig.8 Behavior of the voltage and temperature of the PPy coated sample as a function of the current, measured with voltmeter and thermometer.

Fig.9 Behavior of the impedance and power developed by the PPy coated sample as a function of the current. The values of impedance and power are estimated from data of Fig.8.

About the Authors:

The authors are M.Tech students, in the Department of Textile Technology, PSG College of Technology, Coimbatore-641004

To read more articles on Textile, Industry, Technical Textile, Dyes & Chemicals, Machinery, Fashion, Apparel, Technology, Retail, Leather, Footwear & Jewellery, Software and General please visit http://articles.fibre2fashion.com

To promote your company, product and services via promotional article, follow

this link: http://www.fibre2fashion.com/services/article-writing-service/content-promotion-services.asp