Sachin Pendharkar

Dieffenbacher is a leading manufacturer of press systems and complete production plants for wood-based panels, composites and recycling industries. We combine technologies, processes and application knowhow with extensive client collaboration to create advanced solutions and to help our customers achieve their business goals.

Dieffenbacher supports customers from the initial idea through engineering and plant conception, manufacturing and installation of the press to commissioning and beyond. The Diffenbacher Lifecycle Service offers planning security over the entire service life of the plant. Individual modernisation solutions ensure that production lines can be operated efficiently for years.

'Reduce to the max' means combining multiple advantages in one system, e.g., compact design with more efficient processing at lower costs. That is what our products do. The complete Fiberpress series, for example, is equipped with one pump type. Depending on the required cycle time or press size, only the number of pumps varies, which makes spare parts inventory or supply easier.

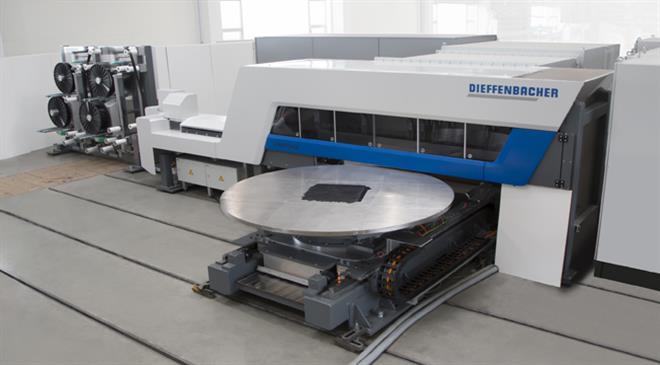

Based on the part to be produced, Dieffenbacher recommends the most economical production process and then implements customer-specific production systems. With its Fiberpress series, Dieffenbacher offers the right press and material infeed technology with sophisticated automation features for the production of Class A exterior parts made of SMC and for underbody components made of LFT-D. The Tailored Blank Line, consisting of Fiberforge and Fibercon systems, enables efficient manufacturing of automotive components such as seat backs or of body armor made of UD fibre tape. Dieffenbacher also supplies systems for HP-RTM, wet moulding and metal-hybrid production processes. (PC)

DISCLAIMER: All views and opinions expressed in this column are solely of the interviewee, and they do not reflect in any way the opinion of technicaltextile.net.