Chunyi Zhi

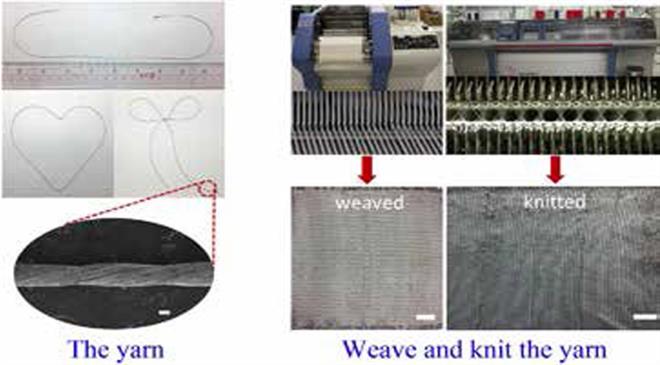

This yarn is drawn and twisted by ultrathin stainless steel 316L filaments which are spun at high temperature. Since the source of yarn is stainless steel, it is inherently highly conductive.

The conductive yarn is an electrode. With two such electrodes and electrolyte, a battery is made.

This high-performance wearable battery imposes two considerable requirements for yarn electrodes: high electric conductivity and high mechanical strength. Although many conductive yarns have been demonstrated (for example, repetitive surface coating of carbon nanotubes (CNTs) and metals, spinning of carbonaceous materials, etc), the two desirable features for batteries are not possessed at least simultaneously, besides the cost-expensive and time-consuming limitations.

The wrist band itself is made up of a cloth weaved by this yarn. The band is an assembly of five cloth batteries in series.

The rechargeability is very important for batteries because it means sustainable use and low cost.

Yes, exactly. Therefore, we call it "rechargeable".

With a power source such as a DC power supply providing current/voltage, the battery is recharged.

The textile battery can be worn to charge various electronic devices, such as watch, sensor, etc. It is not just for medical purposes.

We haven't seen clothes or dresses with this kind of a battery. If all technical issues regarding wearing comfortability and safety etc are solved, the dress itself can be a battery. The battery can also be embedded in part of the dress.

Yes. We plan to commercialise. Before commercialisation, we need to carry out more textile-related studies, such as air permeability, washability, etc, and solve technical issues regarding wearing comfortability and safety, etc.

As most sensors are electronic devices, they need a battery to work. So, we use our yarn battery to power these electronics such as pulse sensor, watch, LED, etc. The pulse sensor can detect the pulse frequency of our heart. Most current batteries are rigid, so they are not flexible and cannot be wearable.

When a dress is a battery, the dress itself can power various portable, flexible and wearable electronics, such as our smart phone, our medical sensor, etc.

Yes. We believe it will be used in fashion industry.

The battery can serve as a power source in a fashion garment. The yarn can serve as an electronic conductor in fashion garment.

The yarn battery can work as a power source; then you don't need an extra one. Between the yarn battery and electronic devices embedded in the garment, you may need conductive yarn to connect them. That is, it needs a conductive yarn to connect the yarn battery with the electronic devices so that the yarn battery can power them. For fashion, you may need electronic devices, such as LEDs, lighting devices, displays (e-ink type or LCD) to enhance their fashion. Moreover, some health monitoring garments may incorporate some sensors, such as strain sensor, UV light sensor, pressure sensor, etc. Our battery can also be used to power these sensors.

DISCLAIMER: All views and opinions expressed in this column are solely of the interviewee, and they do not reflect in any way the opinion of technicaltextile.net.