From WSU’s electrically conductive, cotton-like fibres and MIT’s temperature-responsive FibeRobo, to Singapore’s spider-inspired durable fibres and Canada’s heat and electricity-activated materials, each breakthrough showcases the versatility of smart textiles. The UK’s sustainable textiles with integrated LEDs and sensors, and Finland’s temperature-reactive fabrics further underscore the industry’s rapid evolution. These innovations not only enhance the functionality of textiles but also open new avenues in fields like healthcare, automotive, and fashion, blending traditional craftsmanship with cutting-edge technology.

WSU researchers develop cotton-like fibre for smart textiles: Researchers at the Washington State University (WSU) developed a single strand of fibre that has the flexibility of cotton and the electric conductivity of a polymer, called polyaniline. The newly developed material showed good potential for wearable e-textiles. The WSU researchers tested the fibres with a system that powered an LED light and another that sensed ammonia gas, detailing their findings in the journal Carbohydrate Polymers.

US’ MIT researchers develop shape-changing FibeRobo for smart clothing: An interdisciplinary team at the Massachusetts Institute of Technology (MIT) developed a fibre that could revolutionise the textile industry. Known as FibeRobo, this programmable, actuating fibre can dynamically change shape in response to temperature changes, making it ideal for smart clothing. Unlike other shape-changing fibres, FibeRobo does not require embedded sensors or other hard components, making it fully compatible with conventional textile manufacturing techniques such as weaving looms and embroidery.

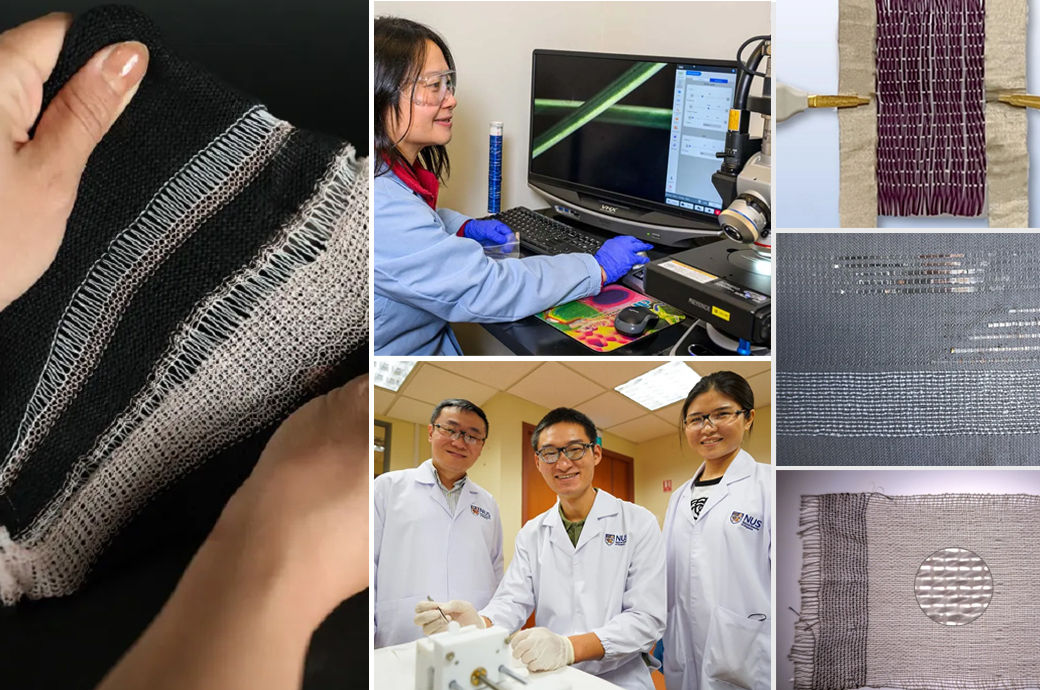

Singapore’s researchers mimic spiders to transform smart textile fibre: Drawing on the intricate spinning process of spiders, researchers at the National University of Singapore’s (NUS) College of Design and Engineering alongside international collaborators created a revolutionary method for producing soft, reusable fibres ideal for smart textiles. These textiles, known for their application in therapeutic, sensing, and communicative devices, require durability, elasticity, and electrical conductivity, all of which this new method fulfils.

Smart fabric by Canadian researchers responds to heat, electricity: Researchers at Canada’s University of Waterloo developed a new smart material that gets activated by both heat and electricity, enabling it to respond to two different stimuli. The unique design paves the way for a wide variety of potential applications, including clothing that warms up while one walks from the car to the office in winter and vehicle bumpers that return to their original shape after a collision.

UK’s researchers develop sustainable smart textiles with LEDs, sensors: Next-generation smart textiles that incorporate LEDs, sensors, energy harvesting, and storage were developed by an international team of researchers led by UK’s University of Cambridge. The textiles can be produced inexpensively, in any shape or size, using the same machines used to make everyday clothing. The findings of the study, which were published in the journal Science Advances, have showcased the potential of smart textiles as a viable substitute for bulky electronics in various industries such as automotive and fashion.

Finland’s researchers develop smart fabric that reacts to temperature changes: Researchers at Finland’s Aalto University and the University of Cambridge collaborated to create new textiles that can alter their shape based on the temperature. Such responsive smart fabrics not only offer adjustable aesthetics but also assist in tracking people’s health, enhance thermal insulation, and provide new tools for controlling room acoustics and design. The team used conventional textile crafting techniques to develop the smart fabric, testing two versions with soft or rigid LCE yarns. All of the LCE fabrics when kept under an infrared lamp contracted as they warmed up. The changes were reversible as they returned to their original shape once the temperature cooled.

Fibre2Fashion News Desk (RKS)