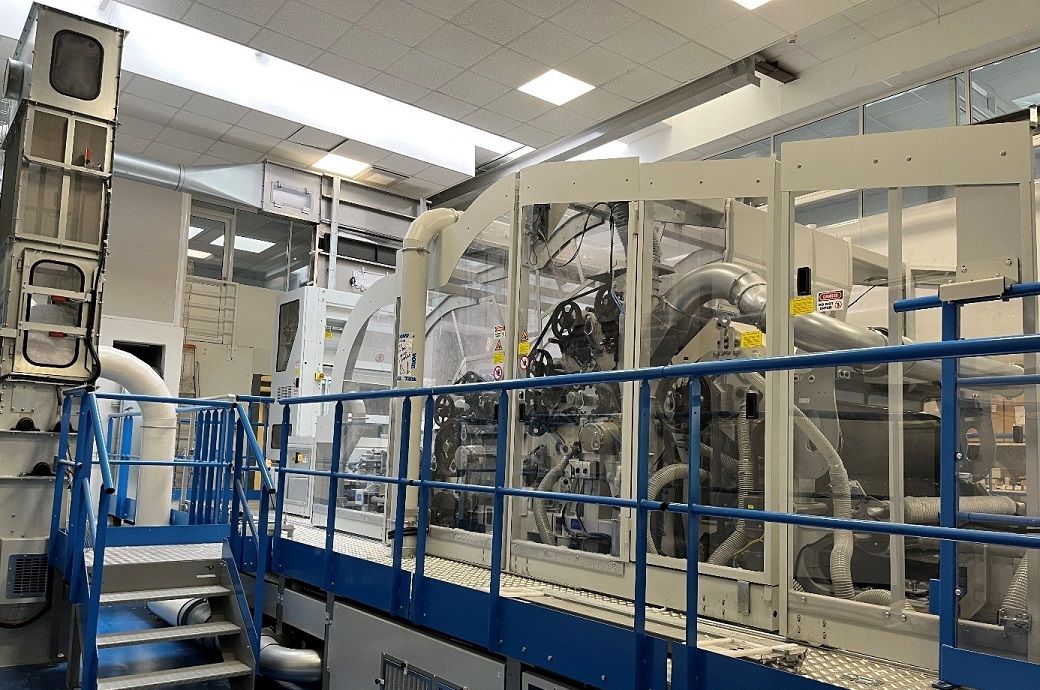

This innovative pilot line has been designed to optimise web forming and entanglement processes, ensuring smooth processing of irregular and sensitive fibres. It features a unique card set-up, designed to maintain fibre quality while achieving remarkable productivity rates, the company said in a press release.

An integral part of the pilot line is the Andritz Metris digitalisation system. This system enables operators to collect and analyse valuable data regarding the line's performance and capacity. This tool is seen as a significant aid for cost optimisation, time saving, and predictive maintenance.

The Andritz Nonwoven team now operates two spunlace pilot lines at the Montbonnot technical centre. The first line is geared toward processing various synthetic and man-made fibres and employs optimised processes such as Wetlace.

Fibre2Fashion News Desk (DP)