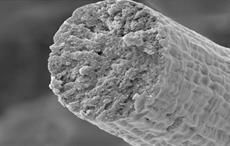

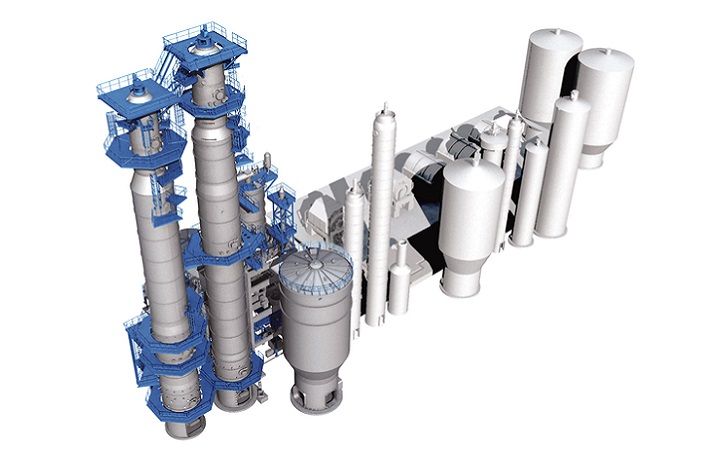

Project STAR is one of the largest and most sustainable pulp mills in the world, operating with the highest environmental standards. It features two flexible, environmentally friendly hardwood fibre-lines for a capacity of 2.6 to 2.8 million tons/year of bleached kraft pulp or 1.5 million tons/year of dissolving pulp made from sustainably cultivated eucalyptus, Andritz said in a press release.

The Andritz A-ConFlex continuous kraft and dissolving pulping technology enables flexibility in production of high-quality dissolving pulp and kraft pulp. With this delivery, Andritz once again confirms its position as the only technology supplier with solid references and experience in continuous cooking of dissolving pulp. With a capacity of 13,000 tons per day, the Andritz Herb recovery boiler is the largest in the world. It will make the mill self-sufficient in energy supply and additionally produce around 180 megawatts of green energy for the Brazilian grid. This covers the energy consumption of about three million people in the region.

The Andritz scope of supply includes a complete, high-capacity wood processing plant, enhanced with state-of-the-art Andritz IIoT Smart Woodyard solutions to ensure optimum chip quality, two flexible fibre-lines with DD-Washer technology, the largest EvoDry Pulp Drying System in the world, with two energy-efficient pulp drying lines and equipped with the Metris DryQ smart pulp drying solution and Metris remote connection to ensure a fast start-up, an Andritz Herb recovery boiler, and a non-condensable gas (NCG) treatment system.

Fibre2Fashion News Desk (GK)