Customers will benefit from the expertise of the Andritz specialists with this fully engineered process, combining both spunlace and wetlaid technologies, so that they can move forward to more sustainable options while maintaining a high level of product quality, in particular by achieving high CD strength and good linting properties, the company said in a press release.

Over the past few decades, Andritz has continued to innovate with various nonwoven processes, like spunlace, Wetlace, and Wetlace CP, with the aim of optimising the use of raw materials and focusing on sustainability by reducing the synthetic fibre content. Facing the growing demand for bio-wipes in parallel with enforcement of the EU’s single-use plastics directive last year, Andritz has decided to go one step ahead to help its customers make the right investments.

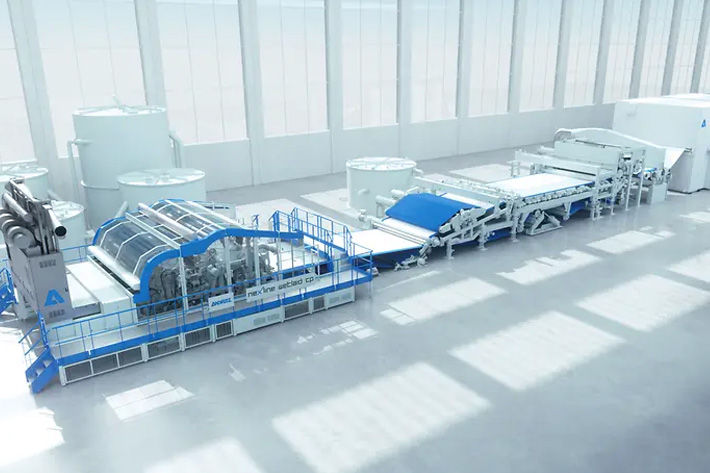

The Montbonnot pilot line has been rebuilt to integrate the new headbox inside the spunlace line. Pulp can be fed in directly and entangled with carded staple fibres to produce unique nonwoven fabrics designed for end uses as bio-wipes.

Fibre2Fashion News Desk (GK)