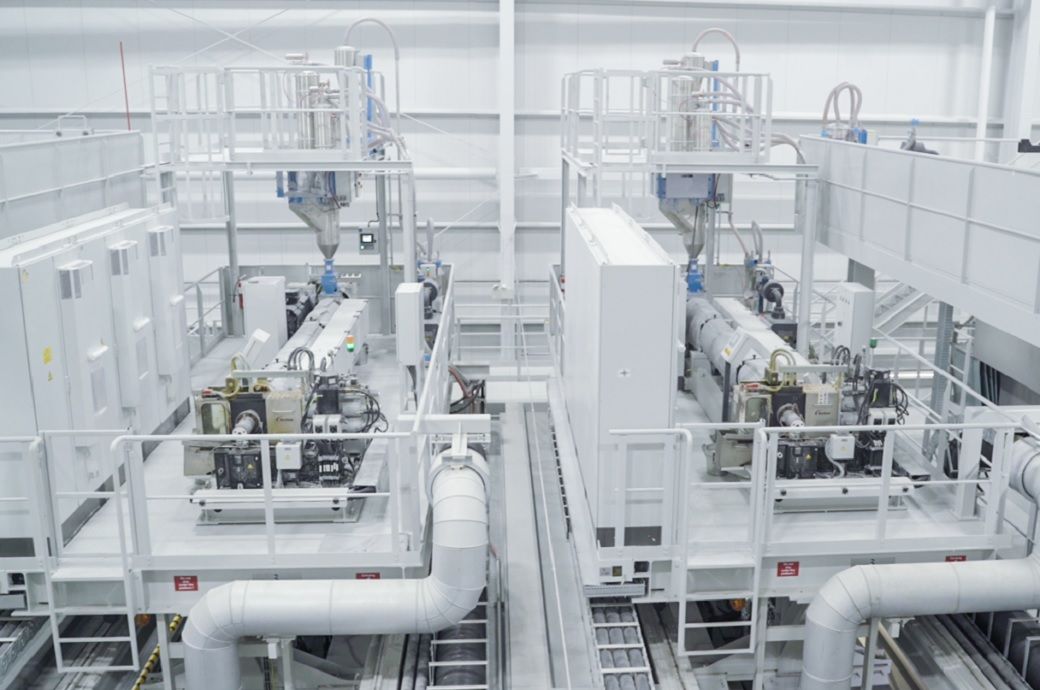

This new, sixth line at the company’s facility in Mocksville will see Avgol investing in new Reicofil 5 (RF5) technology and underlines the company’s commitment to the region as a domestic supplier. The investment will deliver bio-component and corresponding high-loft capabilities, with the line producing materials for applications that meet the needs of upper tier products for hygiene customers, the company said in a media statement.

As part of the investment, Avgol is also introducing extra capacity for meltblown production, ensuring a continuous supply of this critical material for both the region and customers worldwide. Another aspect of the investment includes the addition of cutting-edge lamination capabilities, which enables Avgol to offer enhanced performance products into the existing markets the company serves, as well as to explore new opportunities in other markets.

“The addition of this new line enables us to have even greater production capacity, delivering component materials that are ‘Made in America’ and offering more sustainable options for the growing North America market and around the world. This additional new line also enables the Mocksville facility to deliver additional meltblown nonwovens, ensuring we have extra capacity to meet market demand. Serving the growing baby diaper, adult incontinence and feminine hygiene markets along with satisfying sustained demand for meltblown filtration and medical materials, this investment enables Avgol to deliver an improved degree of service across the entire domestic region while consolidating and strengthening its existing position. The RF5 line, meltblown line and lamination capabilities will provide us a powerful set of platforms as a base from which to provide high-value products for our customers. It will enable us to further diversify the Avgol innovation portfolio while remaining true to our roots,” Avgol CEO, Tommi Bjornman, said.

Fibre2Fashion News Desk (GK)