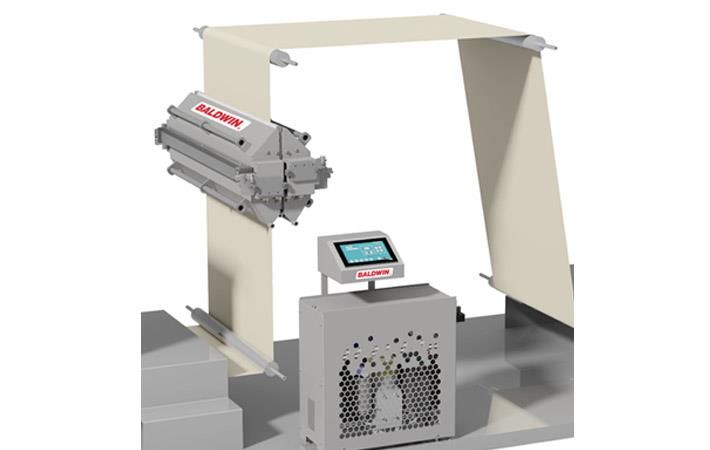

Baldwin Technology Company will showcase its state-of-the-art Spray Applicator at the Techtextil trade fair in Frankfurt, Germany during May 9-12, 2017. The product enables a sustainable textile and nonwoven finishing process, with less energy consumption, a reduction in water waste and chemicals, and a substantial savings of time and money.

Baldwin Technology Company will showcase its state-of-the-art Spray Applicator at the Techtextil trade fair in Frankfurt, Germany during May 9-12, 2017. The product enables a sustainable textile and nonwoven finishing process, with less energy consumption, a reduction in water waste and chemicals, and a substantial savings of time and money.#

Launched in 2015, the Spray Applicator currently is installed at major textile finishing facilities worldwide, with proven positive and 'Sprayvolutionary' results, such as reduced water and chemistry usage by up to 50 per cent, reduced total changeover time by up to 85 per cent and reduced chemistry waste by up to 99 per cent.

Baldwin Technology Company will showcase its state-of-the-art Spray Applicator at the Techtextil trade fair in Frankfurt, Germany during May 9-12, 2017. The product enables a sustainable textile and nonwoven finishing process, with less energy consumption, a reduction in water waste and chemicals, and a substantial savings of time and money.#

The Spray Applicator's individual nozzle control and automatic volume adjustment ensure precise and uniform finishing in various process conditions and production capacities. Because the exact amount of chemistry is applied in relation to cloth width and textile characteristics, no unnecessary energy or chemistry is wasted.

Baldwin Technology Company will showcase its state-of-the-art Spray Applicator at the Techtextil trade fair in Frankfurt, Germany during May 9-12, 2017. The product enables a sustainable textile and nonwoven finishing process, with less energy consumption, a reduction in water waste and chemicals, and a substantial savings of time and money.#

Due to fully automatic flushing, changeover times are significantly reduced. Compared to traditional application methods, with changeovers of 15-30 minutes, Baldwin's Spray Applicator executes the same chemistry change in less than five minutes.

Baldwin Technology Company will showcase its state-of-the-art Spray Applicator at the Techtextil trade fair in Frankfurt, Germany during May 9-12, 2017. The product enables a sustainable textile and nonwoven finishing process, with less energy consumption, a reduction in water waste and chemicals, and a substantial savings of time and money.#

In addition, the Spray Applicator can manage a wide range of low-viscosity chemistries, single- and dual-sided applications and various textile characteristics, as well as wet-on-wet applications, which are performed without any contamination from other chemistry sources. The Spray Applicator's mist containment cover encapsulates and prevents aerosols from escaping, ensuring a healthy working environment.

Baldwin Technology Company will showcase its state-of-the-art Spray Applicator at the Techtextil trade fair in Frankfurt, Germany during May 9-12, 2017. The product enables a sustainable textile and nonwoven finishing process, with less energy consumption, a reduction in water waste and chemicals, and a substantial savings of time and money.#

"With the 'Sprayvolution' concept, we are well prepared to meet the textile industry's increasingly high environmental demands. The Spray Applicator is a revolutionary product, and a small investment that will pay off in a short period of time for our customers," said Per Stenflo, vice president, Spray, at Baldwin. (SV)

Fibre2Fashion News Desk – India