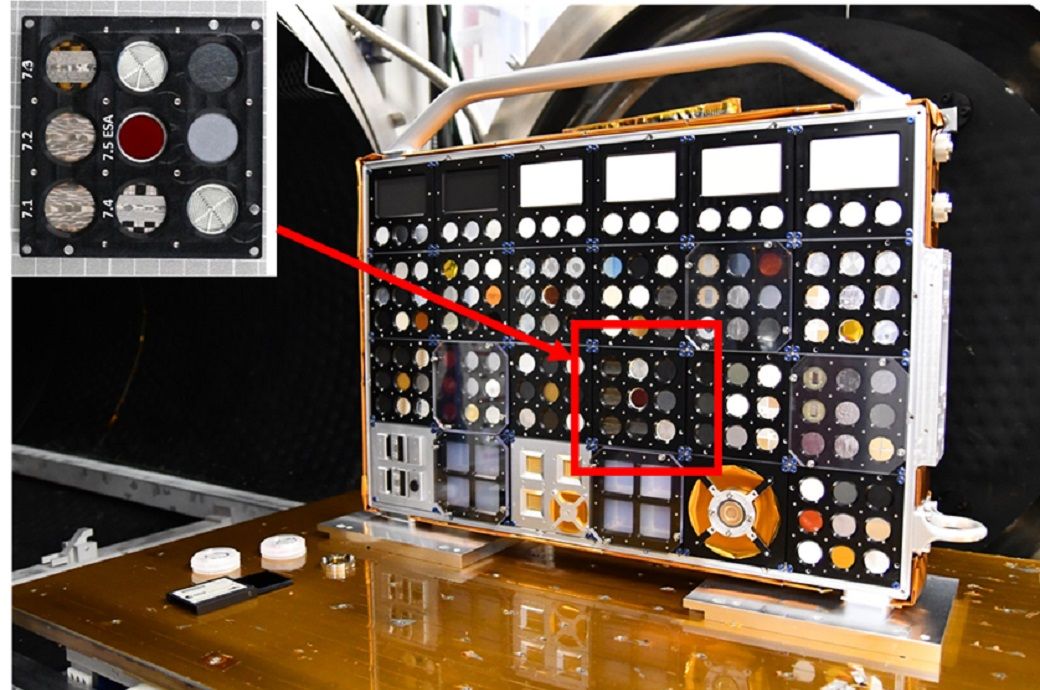

A cutting-edge collection of space materials developed at the University of Bristol took off recently, heading to the International Space Station (ISS). Designed to withstand the brutal conditions of space, these advanced carbon fibre-reinforced composites will undergo rigorous testing on the Bartolomeo platform, mounted at the ISS's front.

The materials, which include four specialised polymers reinforced with carbon fibres and nanoparticles, were specifically crafted to endure temperatures between -150ºC and +120ºC, space debris moving seven times faster than a bullet, intense electromagnetic radiation, high vacuum, and atomic oxygen, a formidable eroding agent. This mission will expose the materials to up to 9,000 orbits over the next 12 to 18 months at speeds reaching 17,000 mph, University of Bristol said in a press release.

Supported by the UK Space Agency (UKSA), European Space Agency (ESA), and other backers like Oxford Space Systems, this research effort also involved early-career researchers, postgraduates, and University of Bristol aerospace engineering undergraduates whose final year projects contributed to the mission. The National Composites Centre, hosted by the University, played a vital role in scaling up the composite materials, marking a significant collaboration effort in the UK’s space research sector.

Prof Ian Hamerton, professor of Polymers and Sustainable Composites in the University of Bristol’s world-leading Bristol Composites Institute, said “Space is the most challenging environment for which to design new materials. You’re pitting your materials expertise, skills and ingenuity against extremes of temperature, mechanical stress, radiation, high speed impacts and more. Any one of those might be difficult, and, unfortunately, gaining access to repair them is not an easy option, so the materials we build must survive without maintenance. The opportunity to test our materials in the proving ground of space is priceless and will help our University of Bristol scientists on the ground improve fibre-reinforced materials for next-generation space missions.”

Dr Ali Kandemir, senior research associate at the University of Bristol said “We want materials that are resilient in the space environment and, importantly, materials that can shield humans from that radiation. We also want to make these materials sustainable, so that when they reach the end of their life they can be recycled and used again for the same purpose.”

Prof Kate Robson Brown, vice-president for Research, Innovation and Impact at University College Dublin, and a collaborator on the project, said “After nearly five years of research to develop novel composite materials for space applications it is very exciting to see our experiment launch to the International Space Station. I am proud to be part of this mission, and to be working with the multidisciplinary and multisector research team to deliver integrated real world and digital testing for innovative materials which will help to drive growth in the new space economy. This mission also demonstrates how space research funding creates career changing opportunities for early career researchers and PhD students in a sector of huge value to both Ireland and the UK.”

Fibre2Fashion News Desk (HU)