Butler Technologies, a leader in printed electronics, has launched its Heatwave Developer Kits, which provide innovators the tools to create with the Butler Technologies’ flexible printed heaters. This gives developers a chance to come up with new designs on their own. The company’s printed heaters are ideal for materials designed to be close to users’ skin.

Often companies dealing with apparel, automotive, medical equipment and other products seeking to incorporate a customisable heating solution into their products will come to a manufacturer with the general idea for how they want the heater to work within their project. The kits, instead, allow these companies’ engineers to come up with their own design before ordering from Butler Technologies.Butler Technologies, a leader in printed electronics, has launched its Heatwave Developer Kits, which provide innovators the tools to create with the Butler Technologies' flexible printed heaters. This gives developers a chance to come up with new designs on their own. The company's printed heaters are ideal for materials designed to be close to users' skin.#

“A collaborative spirit is at the heart of our company’s values,” Mike Wagner, chief operations officer at Butler Technologies, said in a press release. “Offering our customers the opportunity to decrease their development time and costs encourages that feeling, and also provides an intimate understanding of our products.”

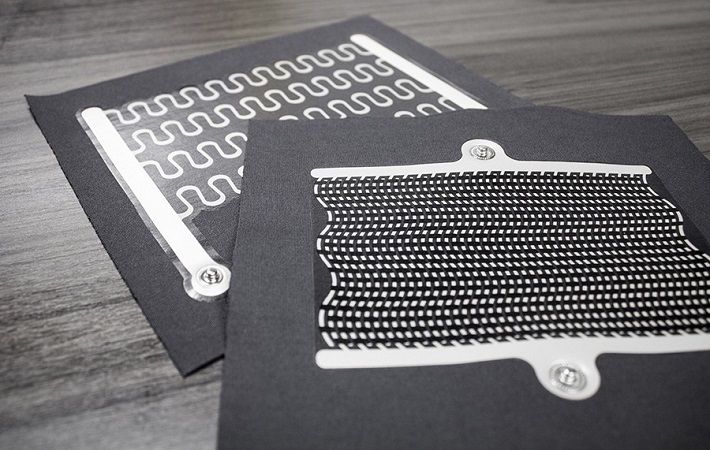

The kits comprise two fixed resistance heaters which are stretchable, flexible and comfortable, and ideal for wearable and textile applications that require stretching such as shirts, gloves, boots or active wear; two positive coefficient heaters (PTC) which are flexible and conformable but without the stretch, making them ideal for applications such as outerwear (coats, skit pants, etc) and medical wearables like heat therapy back braces and heating pads; and power cables and a 12-volt battery pack.

No matter the style, printed heaters stand above traditional wire heaters. Butler Technologies’ heaters are created with a range of conductive inks printed on thermoplastic polyurethane film and can be designed to be self-regulating, meaning they maintain temperature and cannot overheat. These features — along with quality-of-life enhancements, such as being machine-washable — make them ideal for materials designed to be close to users’ skin or indirectly by heating space inside of clothing.

One of the world’s top apparel companies, Ralph Lauren, trusted Butler Technologies to provide warmth to America’s finest athletes by using the heaters in the jackets worn by Team USA at the 2018 Winter Olympics in PyeongChang.

“Our engineers have spent years refining and testing our printed heaters, creating a superior solution to familiar wire-based solutions,” Jamie Orlando, director of sales and marketing at Butler Technologies said. “We’re happy to share our heaters, but be sure, we’ll continue to create new processes, efficient designs and breakthroughs to help businesses thrive.”

Fibre2Fashion News Desk (SV)