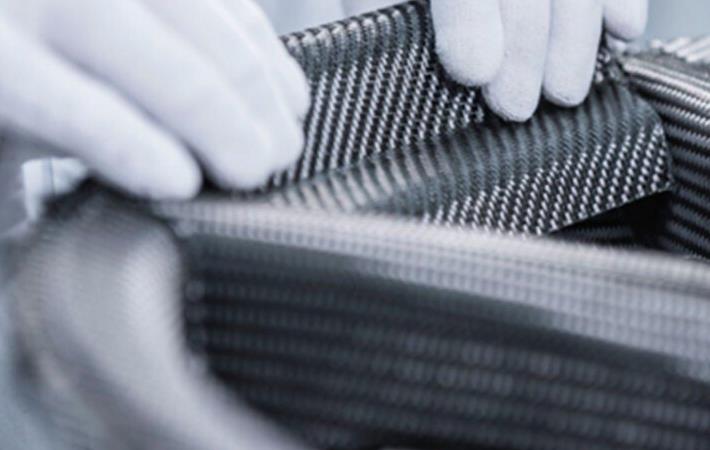

Bureau Veritas has supported LeMond Carbon’s claims of lower costs and increased output regarding its carbon fibre manufacturing process, in comparison to traditional carbon fibre technology. BV carried out an independent technical audit of LeMond’s carbon fibre manufacturing process on a pilot line at Deakin University's Carbon Nexus facility in Geelong.

The verification was done on the basis of the total oxidation time and material properties.Bureau Veritas has supported LeMond Carbon's claims of lower costs and increased output regarding its carbon fibre manufacturing process, in comparison to traditional carbon fibre technology. BV carried out an independent technical audit of LeMond's carbon fibre manufacturing process on a pilot line at Deakin University's Carbon Nexus facility in Geelong.#

Bureau Veritas, a company founded in 1828, is a world leader in laboratory testing, inspection, and certification services. Widely regarded as a trusted brand synonymous with quality, BV is highly experienced at auditing innovative technologies and manufacturing processes.

For the audit of LeMond's technology, BV measured total oxidation times of sub-15 and sub-20 minutes over two separate production campaigns of 24K standard modulus (SM) carbon fibre, achieving fibre tow properties in excess of 270 GPa tensile modulus and 3,500 MPa tensile strength.

The BV audit was conducted on Carbon Nexus's 100 metric ton pilot line which is currently producing samples for trials with LeMond's target customers in several SM industrial markets.

In addition to accurately measuring oxidation times and assuring process traceability, BV oversaw the fibre sampling, packaging and shipping of audit samples for extensive testing at the BV laboratories in Pessac, France. Composite tow tests of the LeMond fibre were completed according to ASTM D 4018-17 standards.

LeMond and Deakin University are teamed to commercialise this innovative technology which enables reductions of 75 per cent and 70 per cent in capex and energy consumption per kilo of output respectively. The rapid oxidation process enables LeMond to produce carbon fibre with the lowest embodied energy of any standard PAN-based carbon fibre available.

“This is a significant milestone for our company. Having our technology independently verified by BV validates the revolutionary nature of our technology," said Greg LeMond, founder and chairman of the Board of LeMond Carbon.

"My team and I are excited to bring our high-performance low-cost carbon fibre to the global market, and look forward to expanding into new markets where the current high cost of carbon fibre has been a significant barrier to adoption."

"Deakin has always been excited about the potential of our patented new technology and it is encouraging to receive independent validation that our technology is effective at scale. We look forward to continuing to support LeMond as they commercialise a lower-cost and lower-emission carbon fibre," said Derek Buckmaster, director Carbon Nexus.

Having proven the capability to successfully produce a competitive standard modulus carbon fibre, LeMond has launched a new capital raise to develop a 5,400-metric ton production facility in Oak Ridge, Tennessee.

Fibre2Fashion News Desk (SV)