Covestro, which is among the largest polymer companies, will exhibit its innovative and sustainable developments at JEC World 2019 to be held during March 12-14 in Paris. It will showcase continuous fibre-reinforced thermoplastic composites (CFRTP) which can be reinforced with carbon or glass fibres and lend parts made thereof low weight yet high strength.

Covestro has been developing material solutions for composites for several years and is now a leading provider. The broad portfolio ranges from polycarbonate and polyurethane (PU) products to film formers for fibre sizings. The range of applications is correspondingly large. It includes wind turbines, photovoltaic systems and auto parts, but also small-scale consumer products such as miniaturised electronic parts and insoles, which are manufactured in large quantities with short cycle times.Covestro, which is among the largest polymer companies, will exhibit its innovative and sustainable developments at JEC World 2019 to be held during March 12-14 in Paris. It will showcase continuous fibre-reinforced thermoplastic composites (CFRTP) which can be reinforced with carbon or glass fibres and lend parts made thereof low weight yet high strength. #

At JEC, Covestro will present itself as a solution provider for various industries and applications. The company will exhibit its innovative and sustainable developments, which often feature the combination of low weight and high strength. Some of these components help to reduce fuel consumption and CO2 emissions in cars, and therefore also contribute to meeting the UN’s sustainability goals.

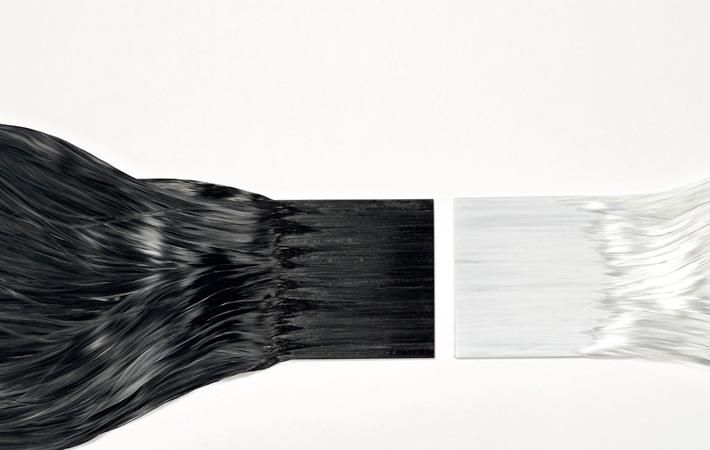

With new composite technology, extra-thin, lightweight, high-strength yet aesthetic parts can be manufactured on an industrial scale. The technology is based on continuous fibre-reinforced thermoplastic polymers (CFRTP) and is sold under the name Maezio. The matrix materials used include polycarbonate, and carbon fibres are added for reinforcement. At its Markt Bibart location, Covestro uses these materials to manufacture unidirectionally reinforced tapes and panels, which are further processed by customers.

These intermediate products are particularly well-suited for producing extra-thin-walled but robust housing parts for laptops and mobile phones. In line with the current trend for thin-walled devices with a cool look, they can also be made with aesthetic surface structures. The single-stage manufacturing process enables shorter cycle times and significant cost savings.

Polycarbonate and its blends, as well as CFRTPs, are the material of choice for producing lighter and more stable honeycomb panels for the interior furnishings in public buses and trains. For this application, the products must comply with specific FST (fire, smoke and toxicity) requirements.

Improving the FST performance of honeycomb panels is an important goal of the new cooperation between Covestro and EconCore. It involves finding the right combination of polycarbonate types and composite materials, and adapting EconCore’s honeycomb technology to meet the requirements. The overall objective is to develop lightweight sandwich panels with higher productivity than conventional composite materials.

A core objective of Covestro’s sustainability concept is to provide active support for climate protection. One key aspect will be promoting renewable energies, primarily wind power. More intensive use in this area will require more cost-effective production of wind turbines with even longer rotors and thus even greater power output.

To achieve this, Covestro has developed a PU resin that, in combination with glass fibre mats and an efficient vacuum infusion process, enables short cycle times and thus cost savings compared with the more commonly used epoxy resin. It is also more robust and should also be suitable for larger sheet lengths. Due to its outstanding mechanical properties, it should also be suitable to produce lighter-weight blades. Last year in China, the company installed its own wind turbines with rotor blades of nearly 60 metres, in order to test the operating capability and stability under practical conditions.

Desmocomp is another highly versatile polyurethane resin, which is ideal for outdoor applications due to its excellent weather and fire resistance. The system can be easily and effectively processed using the pultrusion process. At JEC World 2019 Covestro will present a composite application with this product in the field of solar power. Fiber Profil SL intends to use this Desmocomp aliphatic material for the assembly of large-scale photovoltaic plants and solar thermal systems. For this purpose, the fastening elements must have outstanding mechanical properties, but also need to provide reliable protection against UV radiation.

Also, among Covestro’s wide product selection at JEC World 2019 are its Baybond water-based PU dispersions, which can be used as a film former in fibre sizings to increase the mechanical stability of composites. (SV)

Fibre2Fashion News Desk – India