Royal DSM, a science-based company in nutrition, health and sustainable living, has developed a new glass-filled polypropylene (PP) pellet material, especially for 3D printing, enabling easy and consistent production of structural and demanding applications using fused granulate fabrication technology. PP is the second most frequently used polymer worldwide.

Polypropylene (PP) is widely used for its mechanical, thermal and chemical performance. Automotive, industrial or infrastructure manufacturers looking to adopt additive manufacturing technology for low volume or decentralised production - where the elimination of tools helps decrease cost - desire to use the same material they are familiar with from traditional manufacturing.Royal DSM, a science-based company in nutrition, health and sustainable living, has developed a new glass-filled polypropylene (PP) pellet material, especially for 3D printing, enabling easy and consistent production of structural and demanding applications using fused granulate fabrication technology. PP is the second most frequently used polymer worldwide.#

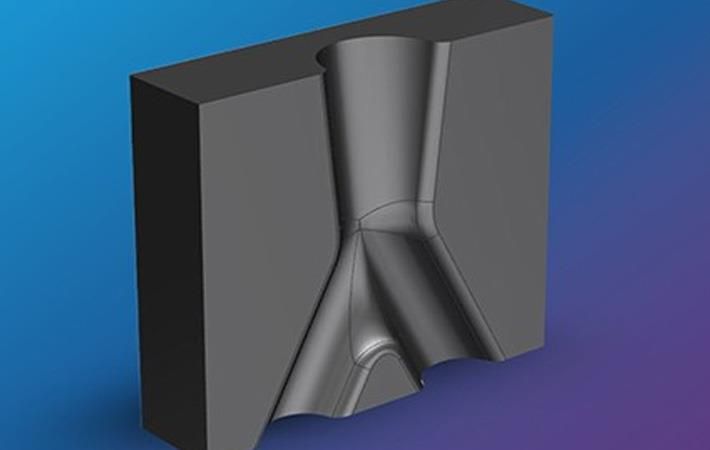

To meet this growing need, DSM introduced the glass-filled PP for fused granulate fabrication (FGF), suitable for additive manufacturing. Arnilene AM6001 GF (G) - the (G) stands for granulates – stems from the same base material used in high volume production and is optimised for FGF 3D printing. By combining materials knowhow, expertise in modeling and simulation, design for additive (vs traditional manufacturing) and printing expertise, DSM secured all of the desirable mechanical, thermal and chemical performance of glass filled PP with the flexibility of a proven 3D process.

The new Arnilene AM6001 GF (G) is ideally suited for direct printing of structural, lightweight applications for automotive, infrastructure and water management, as well as tooling.

DSM additive manufacturing experts worked with equipment partners to validate the material on closed and open chamber build printers to optimise the material for FGF printing. The material’s low carbon footprint, due to reduced energy consumption, and its low LCA (Life Cycle Assessment), inherent to the PP’s chemistry, make it a sustainable solution.

Geoff Gardner, innovations director Additive Manufacturing at DSM, commented: “Availability of engineering-grade materials with the right property set is the next step in the additive manufacturing revolution. Developed by our experts, Arnilene AM6001 GF (G) offers industrial customers an industry standard material with robust mechanical, thermal and chemical performance in an additive manufacturing format. By using a material they already have experience with, they can fully focus on 3D printing and its benefits for their business.”

Fibre2Fashion News Desk (SV)