“The patented continuous process to make light, rigid and strong cores really enables us to deliver unique possibilities to our customers,” said Fabrice Giaume, technical programs leader for DuPont Vizilon thermoplastic composite.

“We also are looking at making honeycomb panels with dissimilar materials, using EconCore continuous process in combination with special high temperature thermoplastic adhesives, such as DuPont Elvamide, offering a wider range of possible applications to the skin core combination,” Giaume added.

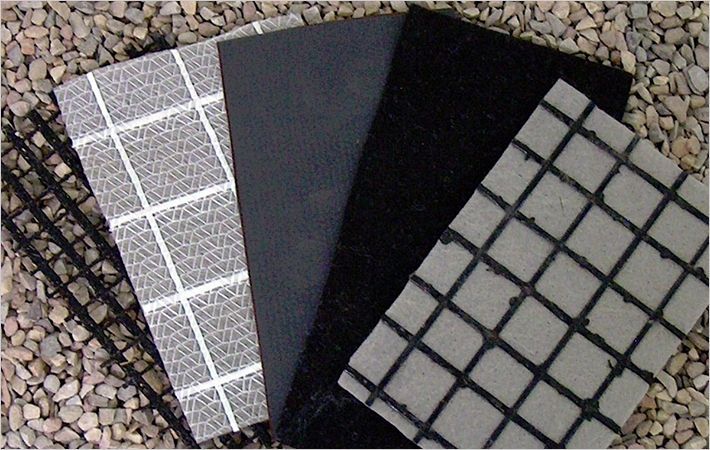

The honeycomb cores are combined with skins made of Vizilon thermoplastic composite, a very light, continuously reinforced fibre composite sheet based on a high temperature resistant, heat stabilised polyamide matrix.

“EconCore’s ThermHex technology for continuous production of sandwich panels with thermoplastic honeycomb core has proven to be capable of delivering high performance sandwich panels at high efficiency and cost levels not achievable for conventional methods,” said Tomasz Czarnecki, technology manager at EconCore.

“We look forward to this new development and believe that materials from DuPont, with their unique set of properties, can offer us the perspective of expanding the spectrum of viable applications. Within the in-line integrated ThermHex technology, Zytel based honeycomb core can be welded with the Vizilon thermoplastic composite, delivering sandwich panels with a very stable core-skin interfacial connection,” Czarnecki added. (NA)

Fibre2fashion News Desk - India