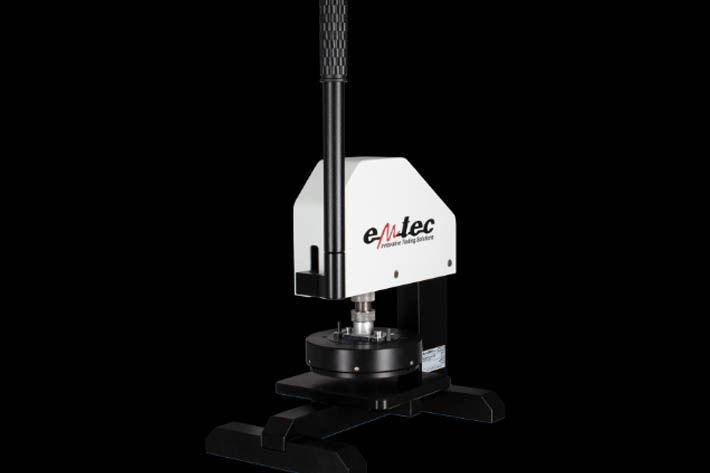

In the exhibition area, professionals in the nonwovens industries will have the chance to exchange ideas and visit exhibitor booths geared toward improving manufacturing processes and product optimisation, such as the German device manufacturer emtec Electronic GmbH. The more than 25-year-old company specialises in the manufacture of measuring and testing equipment for pulp, paper, board, and textiles and serves customers in more than 80 countries around the world, emtec said in a press release.

Emtec representative Thierry Onder De Linden from partnering company ODL Paper will present the TSA Tactile Sensation Analyzer, a digital quality-testing device weighing less than 20 kilograms. The TSA measures along the three basic haptic parameters: micro-surface variations, which determine the feeling of softness, macro-surface variations, which determine the feeling of smoothness, and the stiffness of a material. Besides these three, the device also measures plasticity and hysteresis, which determine the recovery, and the elasticity of nonwovens, including materials with a nonstandard sample size, such as seat belts or diapers. Out of these parameters, a hand-feel value is calculated using special algorithms corresponding to the market where the tested product is intended to be sold and according to its application. These hand-feel values often show a correlation of up to almost 100 percent compared to the human sensory perception as revealed in hand-panel testing.

“Testing the haptic qualities of nonwovens has traditionally been either a very subjective endeavour, or the testing machines are often too large, unwieldy, or the results are unreliable,” explained Alexander Grüner, global marketing and business development manager at emtec. “With the TSA, manufacturers and researchers are able to differentiate between certain haptic traits to arrive at an objective hand-feel value and find the best combination of traits for their finished product.”

Fibre2Fashion News Desk (RR)