EconCore and Covestro have joined hands to combine their technologies for the purpose of producing strong and lightweight honeycomb panels with outstanding performance. One of the targeted key performance aspects is to comply with fire, smoke, toxicity (FST) requirements for public transportation applications, including railway and aerospace.

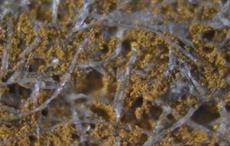

Covestro has developed and tested a wide range of polycarbonates and -blends with specific grades to meet the FST performance required by railway and aviation applications. Furthermore, the company is currently developing a range of lightweight thermoplastic composite solutions under the brand name Maezio. EconCore has developed and patented a unique manufacturing process to produce ultra-light honeycomb structures in an economic way, with a high variety of material combinations that can be fine-tuned in order to meet customers’ needs.EconCore and Covestro have joined hands to combine their technologies for the purpose of producing strong and lightweight honeycomb panels with outstanding performance. One of the targeted key performance aspects is to comply with fire, smoke, toxicity (FST) requirements for public transportation applications, including railway and aerospace.#

Goal of the two companies’ collaboration is to optimise the FST performance of honeycomb panels in order to meet different application requirements. This shall be achieved by selecting the right combination of polycarbonate grades and composites for the honeycomb core and skin and at the same time adapting the parameters within EconCore’s honeycomb technology.

The results of preliminary FST tests, carried out by an independent institute on semi-finished, laminated honeycomb panels, are very encouraging: already at this early stage of development, sandwich-panels with different material and technology combinations have been produced and evaluated, fulfilling critical tests of EN45545 or FAR25.853 standards for various applications. Currently, the positive results of the preliminary FST tests are being verified in detailed investigations of different material combinations.

Ultimate goal of the joint development is to provide sandwich panels that fulfill the technical requirements, offer weight advantages and show better economics compared with currently used composite or metal solutions. The manufacturing process developed and patented by EconCore offers significant cost saving potential due to a high-speed and fully integrated continuous production process, where thermoplastic polymers are directly converted into a honeycomb structure and where, in addition, the sandwich skin layers can be immediately laminated onto core.

“The outstanding manufacturing process of EconCore allows tailoring our materials into lightweight sandwich panel solutions for our customers,” said Klaus Kraner, responsible for mass transportation applications in the Polycarbonates segment at Covestro. “The sandwich technology of EconCore is especially interesting for lightweight applications Covestro is targeting with Maezio,” added Arne Böttcher, responsible for market development of the Maezio brand in the EMEA region.

“After succeeding in other application domains, we have decided to address inquiries of the higher end markets. The process has been proven to work very well with a wide range of thermoplastic materials, including these with FST chemistry, while EconCore’s technology has demonstrated its capability of delivering high-performance sandwich panels at high efficiency and cost levels not achievable with conventional methods,” said Tomasz Czarnecki, COO of EconCore.

Czarnecki adds, “We look forward to this new development and to continuing the partnership with Covestro. The polycarbonate-portfolio of our partner, combined with the composite solutions of Maezio, provides us with the variety and quality of materials needed to meet the high technical requirements in mass-transportation markets. This journey is not only about making thermoplastic honeycomb cores. Imagine the potential benefits for the aerospace industry, if it had the option to thermoform sandwich panels into finished parts in a one-shot operation. The industry, already inclining to monolithic thermoplastic composites, has not seen such a change for decades.” (SV)

Fibre2Fashion News Desk – India