An international team of scientists, led by Professor Monica Craciun from the University of Exeter Engineering department, has developed a new technique using graphene to create fully electronic fibres for clothing. Currently, wearable electronics are produced by gluing devices to fabrics, which makes them rigid and susceptible to malfunctioning.

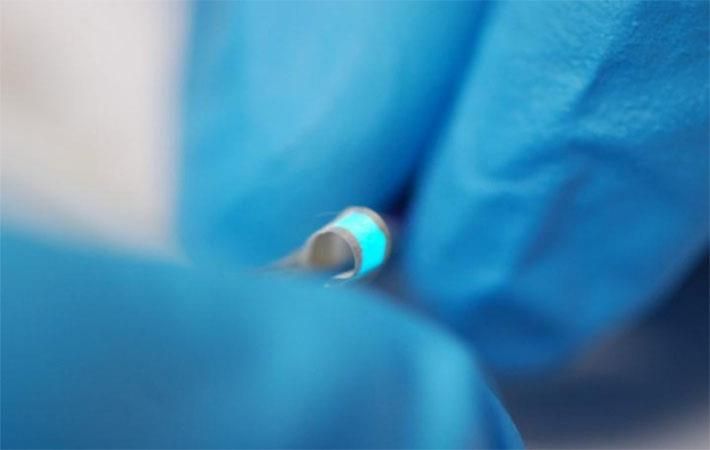

The new technology instead integrates the electronic devices into the fabric of the material, by coating electronic fibres with light-weight, durable components that will allow images to be shown directly on the fabric. The team believes that the discovery could revolutionise the creation of wearable electronic devices for use in a range of applications including health monitoring, such as monitoring of heart rates and blood pressure, and medical diagnostics.An international team of scientists, led by Professor Monica Craciun from the University of Exeter Engineering department, has developed a new technique using graphene to create fully electronic fibres for clothing. Currently, wearable electronics are produced by gluing devices to fabrics, which makes them rigid and susceptible to malfunctioning.#

The international collaborative research, which includes experts from the Centre for Graphene Science at the University of Exeter, the Universities of Aveiro and Lisbon in Portugal, and CenTexBel in Belgium, is published in the scientific journal Flexible Electronics.

Craciun said: “For truly wearable electronic devices to be achieved, it is vital that the components are able to be incorporated within the material, and not simply added to it.”

Dr. Elias Torres Alonso, research scientist at Graphenea and former PhD student in Craciun’s team at Exeter added “This new research opens up the gateway for smart textiles to play a pivotal role in so many fields in the not-too-distant future. By weaving the graphene fibres into the fabric, we have created a new technique to all the full integration of electronics into textiles. The only limits from now are really within our own imagination.”

At just one atom thick, graphene is the thinnest substance capable of conducting electricity. It is very flexible and is one of the strongest known materials. The race has been on for scientists and engineers to adapt graphene for the use in wearable electronic devices in recent years.

The new research used existing polypropylene fibres – typically used in a host of commercial applications in the textile industry – to attach the new, graphene-based electronic fibres to create touch-sensor and light-emitting devices. The new technique means that the fabrics can incorporate truly wearable displays without the need for electrodes, wires of additional materials.

Professor Saverio Russo, co-author from the University of Exeter Physics department, added: “The incorporation of electronic devices on fabrics is something that scientists have tried to produce for a number of years, and is a truly game-changing advancement for modern technology.”

Dr. Ana Neves, co-author and also from Exeter’s Engineering department added “The key to this new technique is that the textile fibres are flexible, comfortable and light, while being durable enough to cope with the demands of modern life.”

In 2015, an international team of scientists, including Craciun, Russo and Neves pioneered a new technique to embed transparent, flexible graphene electrodes into fibres commonly associated with the textile industry. (SV)

Fibre2Fashion News Desk – India