Fibre Extrusion Technology (FET), a supplier of state of the art process technology for the man-made yarns, has reportedly received unprecedented enquiries for non-woven melt spinning system since the onset of Coronavirus. Worldwide demand for medical grade masks has stretched manufacturing capacity which relies on specialist meltblown process for nonwovens.

Fibre Extrusion Technology (FET), a supplier of state of the art process technology for the man-made yarns, has reportedly received unprecedented enquiries for non-woven melt spinning system since the onset of Coronavirus. Worldwide demand for medical grade masks has stretched manufacturing capacity which relies on specialist meltblown process for nonwovens.#

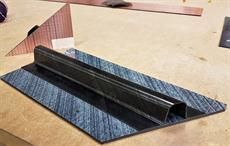

FET’s Melt Spinning system is a tried and tested pilot and laboratory scale format for nonwovens production. Trials are currently being concluded and samples produced of polypropylene melt blown nonwoven materials suitable for applications in FFP2 and FFP3 medical masks.

Fibre Extrusion Technology (FET), a supplier of state of the art process technology for the man-made yarns, has reportedly received unprecedented enquiries for non-woven melt spinning system since the onset of Coronavirus. Worldwide demand for medical grade masks has stretched manufacturing capacity which relies on specialist meltblown process for nonwovens.#

“Although the FET system is primarily designed for R&D and pilot scale applications, trials are proving it to be suitable for low volume production of the face mask central filter materials,” the company stated in a press release.

Fibre Extrusion Technology (FET), a supplier of state of the art process technology for the man-made yarns, has reportedly received unprecedented enquiries for non-woven melt spinning system since the onset of Coronavirus. Worldwide demand for medical grade masks has stretched manufacturing capacity which relies on specialist meltblown process for nonwovens.#

This system is ideal for continued development of nonwoven materials for this application and offers a bespoke solution for small scale production. Indeed, some existing FET customers have already switched their FET Melt Blown Spinning Systems to producing nonwoven materials for such applications.”

Fibre Extrusion Technology (FET), a supplier of state of the art process technology for the man-made yarns, has reportedly received unprecedented enquiries for non-woven melt spinning system since the onset of Coronavirus. Worldwide demand for medical grade masks has stretched manufacturing capacity which relies on specialist meltblown process for nonwovens.#

“FET’s in-house process development laboratory is an ideal and flexible R&D facility and is currently running at full capacity to meet unprecedented demand for specialist nonwoven materials as a result of the crisis,” company stated.

Fibre2Fashion News Desk (JL)