Body components are made from long fiber-reinforced thermoplastics featuring greater structural rigidity thanks to the addition of UD fiber tapes. With the development of tailored fiber placement LFT-D technology, it is now possible to discontinue inline, component-specific unidirectional fiber reinforcement and integrate the reinforcements into the component structure itself.

In order to carry out this process, the tape fiber placement step is introduced upstream of the LFT-D line. The UD fiber tapes consist of glass or carbon fibers embedded in a matrix of thermoplastics and are available as reels of material. The entire procedure required to process the UD fiber tape into the tailored blank has now been integrated into the LFT-D line technology as a fully automated step.

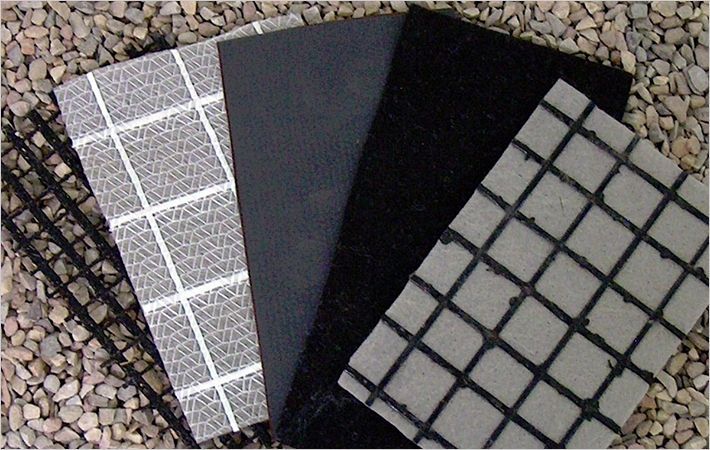

The combination of both materials allows the high strength and structural rigidity features of the fiber tape to be combined with the benefits of the LFT-D compound. Thanks to this plant technology, there is scope for great flexibility in the design of the components. In each plant, a wide range of materials can be manufactured, including pure LFT-D components, pure fiber-tape components, LFT-D components with local endless fiber reinforcement and LFT-D components with all-over fiber-tape reinforcement.

Various material strengths can also be achieved within a single component. Aside from the high degree of flexibility for material combinations, thermoplastics with endless fiber reinforcement offer an affordable, lightweight alternative.

The cost-effective nature of this solution is significantly lower material costs and higher plant productivity resulting from shorter cycle times of less than one minute. Another key advantage is the fact that this group of materials is ideal for recycling, meaning production waste can be recycled within the LFT-D line itself.

Fully Automated Processes for Producing Lightweight Carbon Components

Large-scale batch production and automation for the cost-efficient production of CFK components have been key topics in the automotive, aeronautical and wind energy industries for some time now.

Dieffenbacher has developed a fully automated production line for the production of carbon fiber-reinforced plastic components using the high pressure resin transfer molding process (HP-RTM). The entire production system covers the system units for preform production, the press process and the subsequent reworking of components.

The key technology in this production system is that for producing preforms. The development aimed at fully automating the preform process. This involved looking at the processes for cutting the carbon fiber material, incorporating the cuts and applying the binder material, processing from 2D into a dimensionally stable 3D preform and the subsequent storage in load carriers.