The project addresses the sustainability of nonwovens from different perspectives to improve the raw-material base, processing pathways, circularity, and business approach. SUSTAFIT will support global industrial and societal goals of replacing unsustainable processes and petroleum-based materials with more environmentally friendly solutions, the project participants said in a press release.

The project involves broadly stakeholders in the value chain intending to support them to develop sustainable nonwovens, their raw materials, and production technologies.

“It is vital to build a holistic understanding of sustainability issues in the nonwoven industry. There is a need for further public research to increase usage of biobased and recycled materials,” said senior lecturer Virpi Rämö from the leading partner TAMK.

“The goal is to increase the share of sustainable nonwovens, and possibly even identify new sustainable nonwoven application areas,” outlined Rämö.

The industry partners are helping the project to go in the right and concrete direction. UPM, Fortum, SharpCell, Kemira, Fiber-X, Spinnova, Lixea, Valmet, Nordic Bioproducts Group, Rester, Sulzer, Anpap, NordShield, Lounais-Suomen Jätehuolto, Paptic, JedX Medcare, and Mirka are participating in the project.

Rämö highlights that it is indispensable for the industry to gain an understanding of segment-wise sustainability strategies for nonwovens and the relation of raw materials, processing, and products to make justified decisions for their future sustainable businesses. The new information will also help consumers to make conscious and sustainable choices.

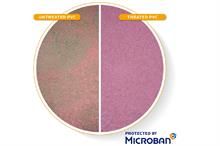

To support the industry concretely, the SUSTAFIT project will develop water-repellent and antimicrobial, bio-based nonwovens. For the moment, insufficient hydrophobicity and antimicrobial performance are two major restricting factors for nonwovens made of man-made cellulose fibres.

TAMK, SUSTAFIT project coordinator, leads the research of sustainable business models and value chains for nonwovens. The organisation will also study the raw material and end-of-life options of sustainable nonwovens, added the release.

VTT will study the segment-wise sustainability strategies and demonstrate the production of different kinds of nonwoven webs. VTT will also create novel concepts and structures to improve their performance.

Aalto University will bring its expertise in producing man-made cellulose fibres (MMCFs) from different raw materials, adding functional properties to fibres and nonwovens, recycling functionalised textiles into new MMCFs, and exploiting the results.

Fibre2Fashion News Desk (NB)