“Valmet IQ is a leading brand in the industry, and this launch demonstrates our ongoing commitment to developing automation technology to meet customer needs in a wide range of industrial processes. The new products bring laboratory accuracy to online measurements. For example, our spectrometer measurements provide new opportunities in measuring functional coatings such as bio barriers, adhesives, and polymers,” said Mikko Viitamaki, business manager, quality management solutions, automation systems business line at Valmet.

Valmet IQ Transmission Spectrum Measurement and Valmet IQ Reflection Spectrum Measurement provide direct, online methods for accurately measuring the proportions and weights of raw materials – such as fibres, water, binders, adhesives, and polymers – using non-contact and non-radioactive technologies. They enable customers to optimise material usage, reduce production costs, and significantly lower their carbon footprint.

The measurements can be applied to a wide range of use cases – nonwoven, extrusion coating, laminating, plastic film manufacturing, and paper and board production. They are essential in enabling the transition to bio-based coating materials, reducing plastic usage, and supporting more sustainable packaging solutions, the company said in a press release.

Valmet IQ Color Measurement uses advanced LED technology to deliver precise reflectance spectrum measurements for paper and board applications, ensuring faster on-spec quality and reduced start-up waste. It detects the detailed effects of furnish, paper dyes, and brightening agents, resulting in more accurate and stable colour uniformity across different paper grades.

Valmet IQ Total X-ray Measurement offers robust and easy-to-calibrate sensor technology for total ash measurement in paper manufacturing. Additionally, the solution can effectively measure glass content in fibreglass and deliver non-nuclear basis weight measurement for nonwoven, as well as coat weight measurement for specialty paper. It ensures real-time process control and proactive issue detection, reducing downtime and minimising waste.

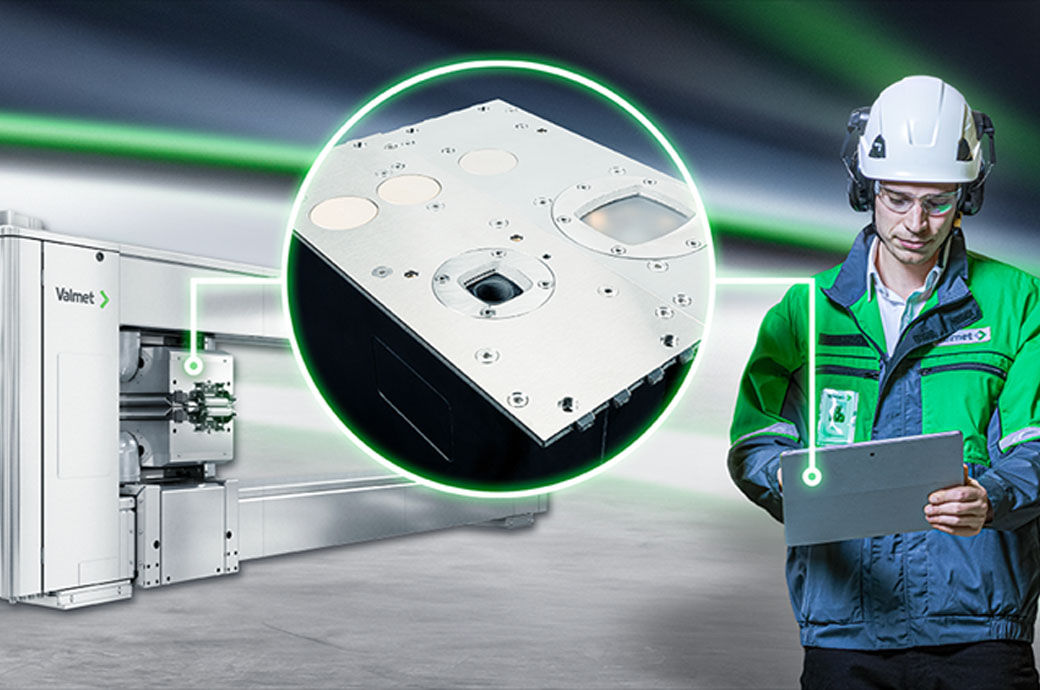

The highly customisable Valmet IQ Quality Control System consists of a scanner, a wide range of online measurements, advanced controls, and applications. It ensures optimal end product quality and production processes.

Valmet has been at the forefront of developing digital solutions for its customers since the 1960s. In 1979, Valmet became the second company in the world to launch a distributed control system (DCS) for process automation, and the company’s first QCS was introduced in the 1990s.

Fibre2Fashion News Desk (RR)