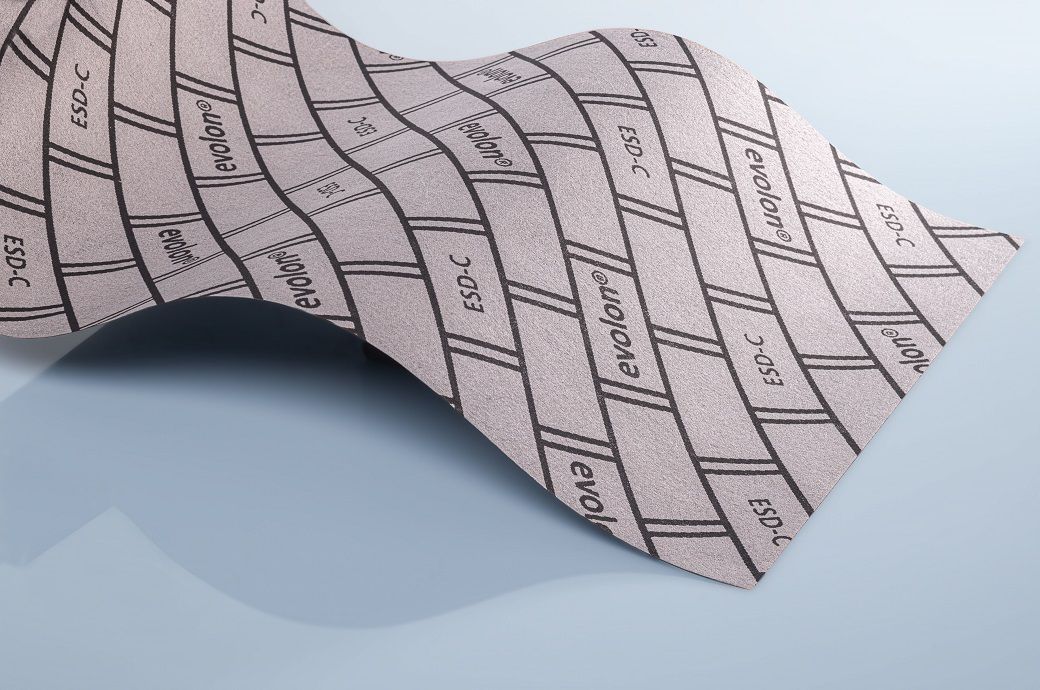

The new technical packaging textile also provides several sustainability benefits: it helps manufacturers to reduce their scrap waste, it is long-lasting, and is made from recycled polyester. The ElectroStatic Discharge (ESD) feature of the new Evolon technical packing textile provides permanent electrostatic discharging protection and the fabric’s surface resistivity can be customised. This eliminates ESD damage to electronic components during transport because electrostatic charging due to movement and friction is safely prevented. As this kind of damage cannot be detected with the naked eye, Evolon ESD helps to avoid failures which can occur after the final product is assembled and released. Manufacturers benefit from fewer complaints and warranty costs, as well as better end customer satisfaction, the company said in a media statement.

Unlike conventional ESD packaging solutions, Evolon ESD also protects parts surfaces by avoiding micro-scratches or lint contamination. By using Evolon reusable packaging to transport parts with highly-sensitive surfaces, customers reduce the number of damaged parts and the reject rate.

Evolon microfilament textiles are also extremely strong and are available in different weights to meet a wide range of requirements – from lightweight to heavy-duty. They can be used to pack and transport very heavy parts without damage. In addition, Evolon fabrics are extremely durable, and contain up to 85 per cent recycled PET.

Fibre2Fashion News Desk (GK)