Hexcel, a global leader in advanced composites technologies, will launch a new government-backed £7.4 million research and development project, MAXIM, and expand its manufacturing facility in Leicester. The project will develop progressive, cost-effective materials and manufacturing solutions for large aerospace and automotive composite structures.

The four-year Multi AXial Infused Materials (MAXIM) project is backed by the UK Aerospace Technology Institute (ATI) and match-funded by the Department for Business Energy and Industrial Strategy.Hexcel, a global leader in advanced composites technologies, will launch a new government-backed £7.4 million research and development project, MAXIM, and expand its manufacturing facility in Leicester. The project will develop progressive, cost-effective materials and manufacturing solutions for large aerospace and automotive composite structures.#

Business Minister Richard Harrington said: “MAXIM is a welcome investment in the Midlands economy and the UK aerospace and automotive sectors, supporting the type of high-skilled jobs we are committed to delivering through our Industrial Strategy.”

“This project will build our expertise and reputation in this cutting-edge field, delivering world-leading research and development on the production of new composite materials for large structures. This will enable composite structures such as aircraft wings and car bodies to be manufactured faster, greener and more cost-effectively,” Harrington added.

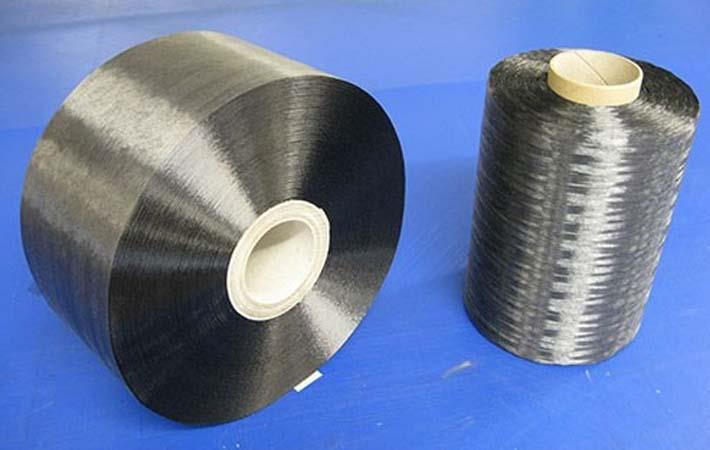

Most large aerospace composite parts are made from “prepreg” where the carbon fibres and resins have already been combined. Converting this material into solid parts requires huge pressurised ovens, known as autoclaves. The MAXIM project will explore the manufacture of new carbon fibre fabric forms and resins that can be made into parts without using autoclaves. The aim is to enable complex metal structures, such as aircraft wings, to be manufactured more cost effectively and at faster production rates from composites.

Composite structures are around 25-30 per cent lighter than metal equivalents, delivering positive environmental benefits. For example, by making aircraft lighter they will use less fuel and produce fewer carbon dioxide emissions.

Hexcel is investing in expanding its Leicester plant by installing a state-of-the art machine for carbon non-crimp fabrics development and lab equipment for research into this technology. The company will be working closely with the National Composites Centre to leverage their expertise in material handling and part processing.

Hexcel’s Thierry Merlot, president – Aerospace, Europe/MEA/Asia Pacific said:

“Investment in this project in Leicester will allow Hexcel to advance key out of autoclave technologies that can provide a step change in the cost-effective production of composite parts for commercial aircraft and passenger cars. The project will support the development of new materials that the aerospace industry in particular can adopt with confidence to meet the high build rate requirements for future programmes.” (SV)

Fibre2Fashion News Desk – India