Visitors will also see a wing box demonstrator made from HiTape dry carbon reinforcements. Both parts were injected with Hexcel's RTM6 infusion resin and incorporate a toughening veil to enhance mechanical properties to meet the structural requirements for aerospace parts, said Hexcel in a press release.

With 50 years of experience and the most qualified carbon fibre positions on aerospace programmes in the industry with its comprehensive range of high-strength, high-strain PAN-based carbon fibres, Hexcel continues to innovate and is introducing a new fibre to its portfolio. HexTow HM54 combines high modulus and high tensile strength, which allows structural designers to achieve higher safety margins for both stiffness and strength-critical applications. HexTow carbon fibres are excellent not only for aerospace applications but also industrial and recreational applications. HexTow carbon fibres are excellent not only for aerospace applications but also industrial and recreational applications; examples of golfing applications will be on display.

Additive manufacturing is on the forefront of innovation for composite technologies, and Hexcel is leading the way with its HexAM additive manufacturing process. HexAM additive manufacturing combines high performance Pekk thermoplastics with carbon fibre to produce flight-ready 3D printed HexPekk parts. HexPekk structures offer significant weight, cost and time-to-market reductions, replacing traditional cast or machined metallic parts in highly demanding aerospace, satellite and defense applications.

HexPly M77 snap-cure prepregs are yet another example of Hexcel technology leading the way. HexPly M77HF, the latest member of this quick-curing prepreg family, is revolutionising the world of composites for high-performance sporting goods with its faster production times and excellent surface quality. It will be featured in the Hexcel booth in two products – a carbon fibre Goode water ski which is setting records in the competitive world with its precision and durability, and in a HED cycling wheel noted for its aerodynamics and light weight.

Among Hexcel's latest technologies are the RF Interference Control materials made by ARC Technologies, a Hexcel company. A selection of these industry-leading custom RF/EMI and microwave absorbing composite materials for military, aerospace and industrial applications will be on display at the Hexcel booth.

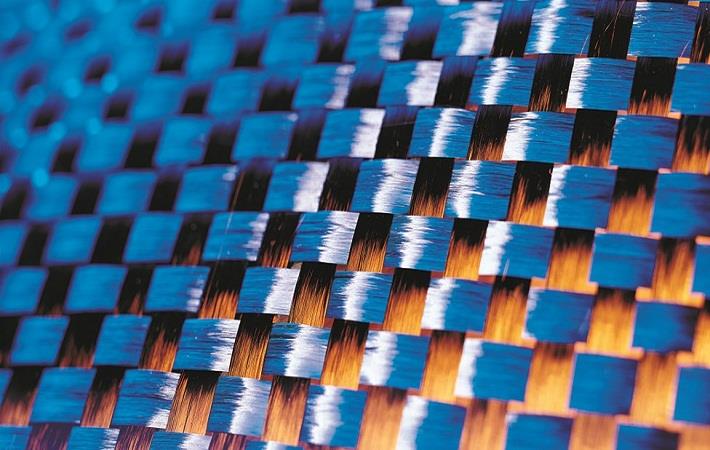

HexForce bias weave woven reinforcements are a patented solution to optimise material usage. These bias weave reinforcements are continuous rolls of carbon fibre fabric in which the warp and industrial applications. (PC)

Fibre2Fashion News Desk – India