The Hohenstein Institute, an international research centre involved in the development, testing, and certification of textile products, has announced the launch of an ergonomically optimised work jacket for the optimum use of an exo-skeleton for overhead work. The product is a created in a ZIM joint project, a funding programme, with five partners.

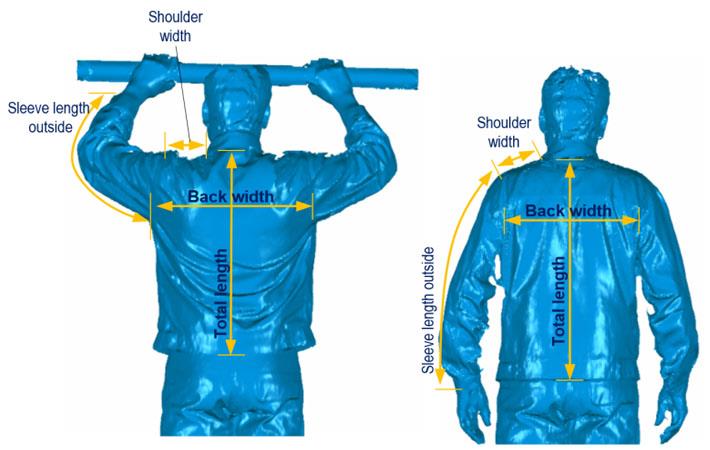

To ensure that the work jacket best meets the physical requirements of the target group, around 17,000 3D whole body scans from the Hohenstein data pool were used to create a cluster for the target group “Overhead Worker”. A technical clothing design was then developed which includes the technical spacer fabrics for the reduction of pressure and regulation of the braces (contact surfaces of exo-skeleton) in the upper and lower arm area and also in the entire shoulder area to improve wearing comfort.The Hohenstein Institute, an international research centre involved in the development, testing, and certification of textile products, has announced the launch of an ergonomically optimised work jacket for the optimum use of an exo-skeleton for overhead work. The product is a created in a ZIM joint project, a funding programme, with five partners.#

To ensure movement freedom in the shoulder/armhole area, an elastic insert has been included in the design. The stretch zone permanently reduces the effort required to carry out the movements. In order to best cater for all body sizes, a two-way zip has been integrated for the flexible regulation of hip width. In addition, the sleeves are fastened with a cutting technology sleeve hem variant with thumb hole. The materials were selected with consideration of thermo-physiological and skin sensory aspects so that an ergonomic work jacket exo-skeleton system was created in its entirety.

The work jacket and exo-skeleton reduce the health effects for employees who carry out overhead work, and this, thus reduces outage time for employees.

The ZIM project was supported by the Federal Ministry for Economic Affairs and Energy. The project partners were Fraunhofer IPA Stuttgart, EGEAS GmbH & Co. KG, CONTAG AG, BE-Power GmbH, ISG GmbH, and Hohenstein Institut für Textilinnovation gGmbH. (GK)

Fibre2Fashion News Desk – India