The technology has been granted patents in India, the United Kingdom and the United States.

Continuous mass production of nanofibres over a wide width, high rates of deposition, uniform deposition, production of low diameter fibres and adhesion are some of the challenges encountered during the deposition of nanofibres on substrates.

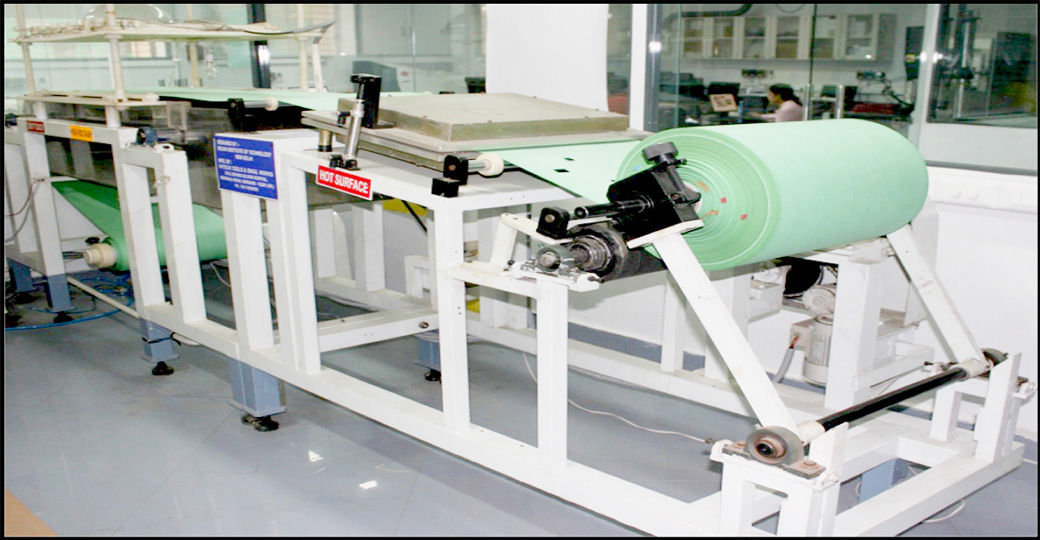

The researchers, led by Ashwini Agrawal and Manjeet Jassal from the textile and fibre engineering department, could address all such challenges and develop a scalable prototype.

“There are a few manufacturers outside India that make continuous electrospinning machines. However, their products suffer from non-uniform deposition when low add-ons are required, which is an essential requirement for a cost-effective solution. In India, there is no company engaged in the mass production of nanofibers,” Agarwal said in an IIT-D release.

“Our research group is the first one to develop technology for continuous production of nanofibres over a large width of substrate suitable for various applications”, he said.

The high-efficiency fuel and oil nanofibre filters developed were found to be stable during the mechanical fabrication process and then during the life of the filter.

“The technology is a game changer for meeting tighter standards of vehicular pollutions, for protection of individuals from rising air pollution, and health care devices, etc.,” Agrawal added.

Fibre2Fashion News Desk (DS)