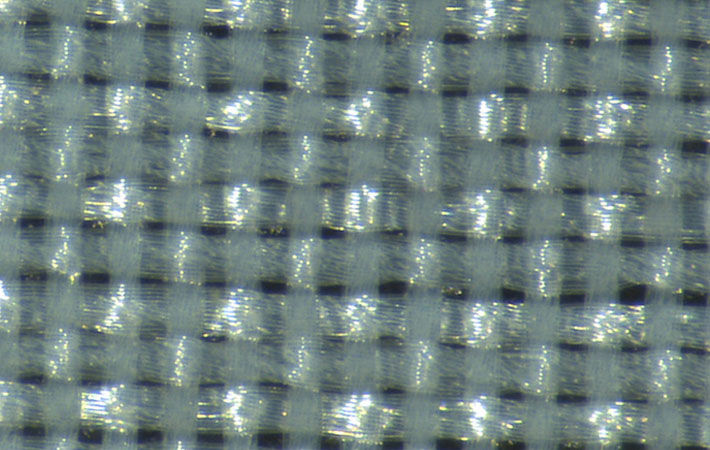

Condensed fabrics utilise a proprietary process developed at Aran Biomedical, ensuring textile based finished devices and components are available at their lowest thicknesses. Our process typically leads to a minimum reduction of 50 per cent, but this can be as high as 70 per cent depending on the configuration. An additional benefit of fabric condensing is reduced permeability as yarns flatten and spread out, without affecting the mechanical characteristics of the fabric. Woven fabric that has been condensed from 70 microns to 35 microns thick, shows a reduced permeability range between 300 – 350 ml/cm2/min, the company said in a press release.

These woven textiles are predominantly used in the structural heart and vascular spaces, more specifically for the development of heart valve skirts, occlusion devices, synthetic grafts, vascular stents, and endovascular devices. Aran Biomedical believes this new technology expansion will lead to further profile reductions in established devices and potentially lead to the development of more minimally invasive therapies in space. This technology expansion compliments Aran Biomedical's established platform technology, ValvTEX. This proprietary technique creates suture free textile covering for mitral, aortic, and tricuspid heart valves.

Fibre2Fashion News Desk (GK)