Take the automotive industry as an example. It is moving away from old, polluting products to greener, leaner, and smarter vehicles. Demand that has contributed to the global market for lightweight automotive materials now being projected to surpass $99 billion by 2025. But to achieve this, new materials are needed, which is one of the markets that Nemo Nanomaterials addresses. Modern vehicles present unique demands for materials and require them to be light and durable while providing electrical conductivity as well as electromagnetic shielding. Most importantly, all materials used must be sustainably managed throughout the product lifecycle. Invariably, this has seen manufacturers making trade-offs when it comes to material properties and functionality, the company said in a press release.

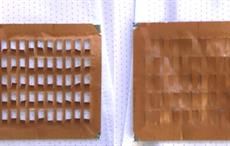

However, with Nemo Nanomaterials, the industry challenges have become a thing of the past. Nemo's proprietary technology and techniques for processing and mixing carbon nanomaterials enhance plastics with features of metals for advanced electronic systems, under the hood parts, fluid supply lines, battery casings, internal and structural components, with reduction of up to 30 percent of the weight for parts when compared to metals.

Beyond the automotive sector, Nemo Nanomaterials technology can be applied to electronics, textile, construction, telecom, energy, the aviation and aerospace sectors. Nemo's technological breakthrough is the sole enabler for replacing metals with plastic materials - by achieving desired electrical conductivity and EMI shielding properties while maintaining the original features of the plastic. On EMI shielding and electrical conductivity alone, the company can reach an addressable market that surpasses $10 billion. And that is just one of almost limitless applications and possibilities.

“High-end carbon nanomaterials have been known to mankind for decades. They recently were made available on a commercial scale. Many companies have made lots of promises in regard to making real industrial products out of them, but Nemo is unique in making them a reality. Nemo's technology enables a revolution in nano-carbons. It solves many wide and acute industry challenges across a myriad of specifications while delivering ready-to-use additives that can be used by the industry utilising existing machinery and procedures. Nemo Nanomaterials is going to provide materials that are required for the future of manufacturing,” Jonathan Antebi, co-founder and VP business development at Nemo Nanomaterials said in a press release.

With Nemo Nanomaterials technology, there is zero performance trade off in materials while enabling innovative design and functional possibilities across industry sectors. Its additive means customers can more efficiently use raw materials while also delivering the most effective end-of-life recyclability possible.

“Refineries, and not petroleum, reshaped the world because they provided new materials that enabled new industrial capabilities. With Nemo Nanomaterials, high-end nanocarbons are just as transformative to reinventing the world of the future, today,” Alexander Zinigrad, co-founder and CEO of Nemo Nanomaterials said.

Fibre2Fashion News Desk (GK)