Due to increasing demand and limited global supply, there is a strong need to develop new, efficient technologies for its production. The catalyst is highly active, selective, stable and utilises carbon dioxide (CO2) efficiently. One promising technique for producing propylene is a chemical reaction, called oxidative dehydrogenation, that uses CO2 to convert propane gas into propylene by removing hydrogen. However, existing catalysts used to speed up this chemical reaction are not very efficient, according to a press release by the university.

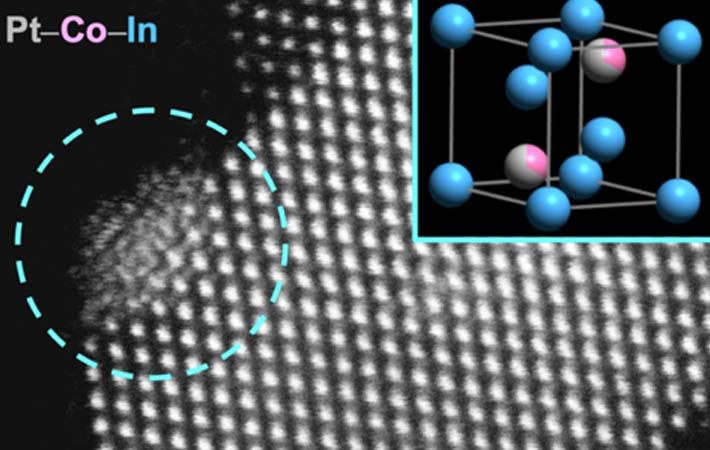

To achieve this, Hokkaido University molecular engineer, Shinya Furukawa and his colleagues developed a catalyst made from three different metals (platinum, cobalt and indium), each chosen for its specific properties. Platinum was selected as the main active metal because of its ability to break chemical bonds between carbon and hydrogen, enabling the dehydrogenation reaction. Cobalt accelerates CO2 capture and activation, while indium enhances the catalyst’s selectivity. The metals were fixed to a support made from cerium oxide, a compound commonly used in car catalytic converters.

The researchers tested the catalyst’s activity at 550°C and compared the results with existing catalysts. They also performed a mechanistic study to understand the functions of the different components and found the catalyst links the propylene-forming reaction to the deoxygenation of CO2, and ensures the catalytic activity is specific to propane; water and carbon oxides are formed as by-products. Further, they found that the catalyst increased the reaction rate approximately five-fold compared to the typical values reported from other systems. The reaction produced a higher ratio of propylene and utilised more CO2 at 550°C compared to previous catalysts. The catalyst also showed good long-term stability and reusability. This study provides new insights into the design of highly efficient catalysts for petrochemical production, and has potential benefits for carbon recycling and greenhouse gas reduction, according to Hokkaido.

“The challenge is to develop a catalyst that will activate both reactants – propane and CO2 – without unwanted side reactions. It also needs to be stable and reusable in the long term. To date, no other catalyst has been shown to simultaneously exhibit a high catalytic activity, selectivity, stability, and CO2 utilisation efficiency. Our multifunctional material meets all these requirements,” Furukawa said in a statement.

Fibre2Fashion News Desk (GK)