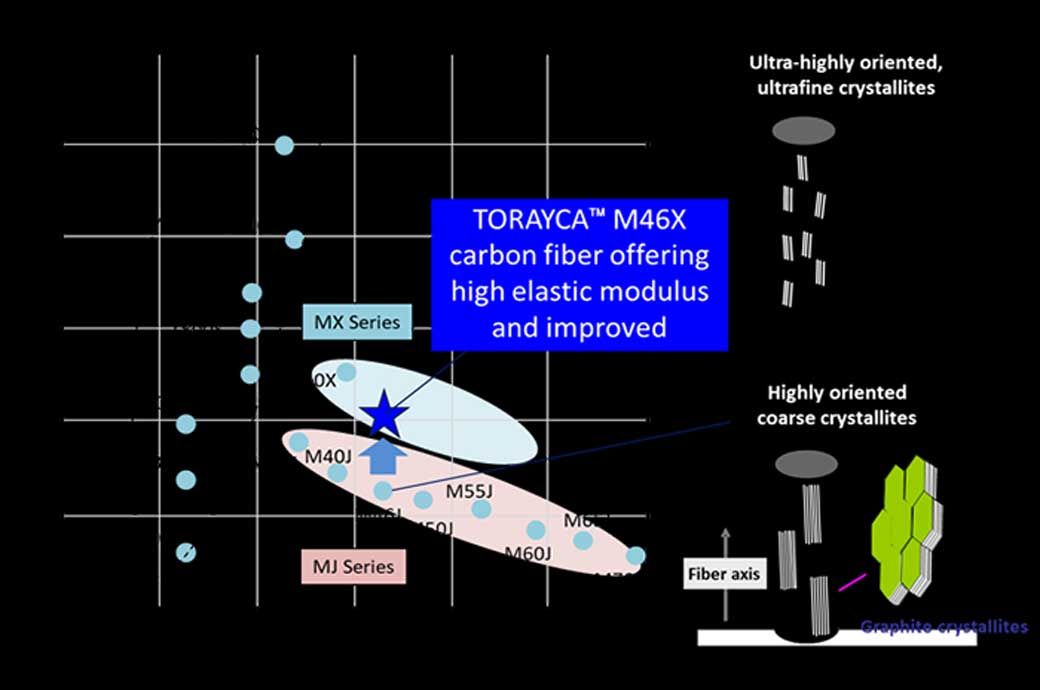

Typically, there is a trade-off between the tensile modulus and strength of carbon fibre. Boosting the strength while maintaining the modulus of carbon fibres with a tensile modulus exceeding 350 GPa presents technological challenges. However, the sporting and leisure goods market demands both qualities to maintain performance while utilising less carbon fibre to lower the weight of molded parts.

Toray developed the Torayca M46X by pushing the structural control technology envelope. Nano-level controls of the graphite crystallite structure inside fibres resulted in an ultrafine, ultrahigh orientation producing carbon fibre that is more than 20 per cent stronger than conventional materials while maintaining its tensile modulus, the company said in a media release.

The company will also deploy Torayca M46X prepreg, with the resin matrix utilising the proprietary Nanoalloy 1 microstructure control technology. The new product will significantly enhance compressive strength to boost stiffness while retaining strength, reducing the weight of finished products and broadening design flexibility.

Developing high-performance carbon fibres with a high tensile modulus exceeding 350 GPa began with Torayca M40 with graphitised yarn2. Successors were Torayca M40J in 1984 and Torayca M46J in 1986 in response to robust demand for the high-modulus Torayca MJ carbon fibre series. Toray continued to develop technologies to balance the tensile strength and modulus. The Torayca MX series was created by applying technologies to control graphite crystallite structures and orientations inside fibres. The first offering in this series was the Torayca M40X, launched in 2018. This product has since earned a solid reputation as a high-performance carbon fibre and prepreg (a resin-impregnated intermediate base material) matching market requirements.

In line with its corporate philosophy of contributing to society by creating new value, Toray will continue developing new products that help transform the economy through the enhanced performance and processability of Torayca carbon fibre and prepreg.

Fibre2Fashion News Desk (RR)