Amidst shortages of personal protective equipment, scientists at Korea Advanced Institute of Science and Technology have developed a reusable nano-filtered face mask. The nano-filter maintains excellent filtering efficiency even after hand washing, they say. They have used a technology that aligns nanofibres in orthogonal or unidirectional directions.

Korea has seen rationing of masks. The face masks most commonly used are disposable ones, originally made for filtering out up to 94 or 95 per cent of fine dust, referred to as N94 or N95 masks.Amidst shortages of personal protective equipment, scientists at Korea Advanced Institute of Science and Technology have developed a reusable nano-filtered face mask. The nano-filter maintains excellent filtering efficiency even after hand washing, they say. They have used a technology that aligns nanofibres in orthogonal or unidirectional directions. #

The proprietary technology aligns nanofibres with a diameter of 100~500 nanometres in orthogonal or unidirectional directions. This reusable nano-filtered face mask could help to relieve the challenges arising from the supply shortage of face masks.

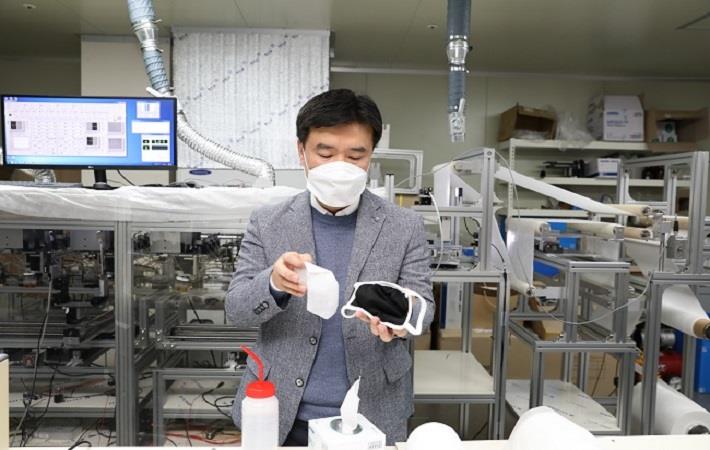

Professor Il-Doo Kim’s nano-fibre filtered mask will maintain its sturdy frame and filtering function even after being washed more than 20 times. Kim, who has continued to study the filtering of fine dust using nano-filters.

Kim used an insulation block electrospinning process to manufacture orthogonal nanofibres by controlling the alignment of nanofibres. This structure can minimise delivering of the pressure toward the air filter and maximise the filtration efficiency, which is different from existing disposable masks without nano-fibres.

Existing masks also fail to maintain their air filtering function because their electrostatic function disappears when exposed to water. Thus, their filtering efficiency is reduced significantly, making it almost impossible to reuse them. However, this nano-fibre design was proven to be water resistant with more than 94 per cent filtering efficiency in 20 repeated bactericidal tests with ethanol. The nano-fibre mask also showed no deformation in its nano-membrane structure despite the 20 hand washes. In particular, it was confirmed that there were no deformations in the membrane, even after soaking in ethanol more than three hours.

Kim said, “We believe that this mask can be reusable for about a month even after washing in ethanol. The inner filter can also be replaced.” He added, “We found that the mask filters out up to 80 per cent of 600-nanometer particles even after undergoing a bending test more than 4,000 times.”

Kim established his startup company, the “Kim Il-Doo Research Institute,” last February. It can currently produce 1,500 nano-fibre filters per day.

Fibre2Fashion News Desk (SV)