Mitsui Chemicals Asahi Life Materials intends to establish the production setup for regular and thermoformable grades of this nonwoven before the end of 2024. Applications being eyed cover a wide variety of industrial fields, including beverage filters and packaging materials that come into contact with food, along with agricultural materials, the company said in a press release.

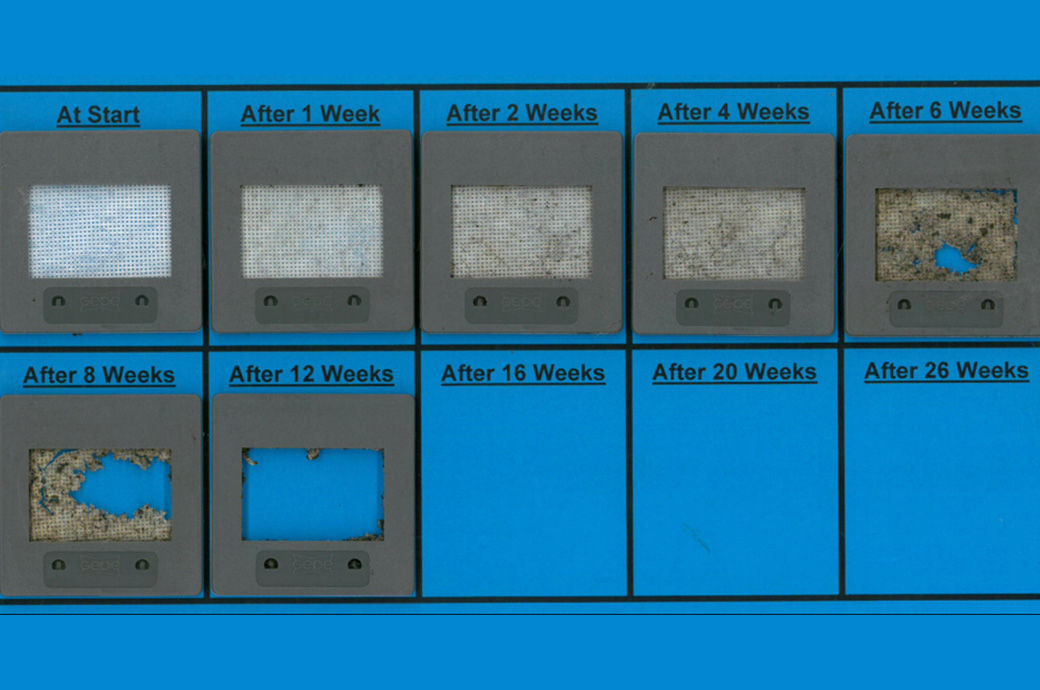

The newly developed biodegradable plastic’s key feature is its capacity to decompose in a home composting environment at a temperature of around 28 degrees Celsius.

Biodegradable plastic has all the durability of ordinary plastic, but is broken down after use into water and carbon dioxide via the action of microorganisms found in nature. The material is attracting increasing attention due to the potential for its widespread use to reduce the environmental impact of plastic. Different biodegradable plastics are able to break down in compost, soil, water and other such environments, so each biodegradable plastic is categorised according to the specific environment in which it decomposes.

Composting uses the power of fungi and other microorganisms to break down organic waste. Amid growing awareness of composting as a mechanism for turning kitchen waste, fallen leaves and more into fertiliser, concern about environmental issues is driving increased interest in the practice, especially in western countries, the release added.

Biodegradable plastic composting includes ‘industrial composting’, which takes place at high temperatures in urban waste disposal facilities; and ‘home composting’, which takes place in ordinary household settings.

Mitsui Chemicals Asahi Life Materials intends to continue developing materials designed with eco-friendliness in mind, and aims to see such materials adopted in as many industries as possible.

Mitsui Chemicals Asahi Life Materials offers Ecorise, a range of environmentally friendly spunbond nonwovens made primarily from polylactic acid (PLA), a plant-derived biodegradable plastic. Able to decompose and be composted under industrial composting conditions, Ecorise meets standards laid out by a number of domestic and foreign certification bodies, including the US-based BPI, Austrian-based Tuv Austria (via its certification center in Belgium) and Japanese-based JBPA. This has seen the material receive certifications such as BiodegradablePla and BiomassPla.

The ability to bestow Ecorise with diverse properties – including high uniformity, breathability, flexibility and press moulding compatibility – has seen it meet with high praise in a wide range of applications, from food packaging materials used in tea and coffee filters through to agricultural and industrial materials.

Fibre2Fashion News Desk (RR)