MP hygiene, a French Company situated in Annonay Ardeche Department on Rhone-Alps Region, has closed the purchase of a state of the art tissue line with an average production of 100 tpd from Toscotec. The new line will allow the Company to guarantee its own requirements for the existing converting facilities. The machine is expected to come on stream on first quarter of 2013.

MP hygiene has a diversified range of cleaning products, from paper wipes to textiles, nonwovens and hand-cleaning lotions and foams. Principally manufactures and sells paper refills on the professional market, round products such as hand towels rolls, industrial rolls or toilet paper, and flat products such as W or Z fold towels.MP hygiene, a French Company situated in Annonay Ardeche Department on Rhone-Alps Region, has closed the purchase of a state of the art tissue line with an average production of 100 tpd from #

In 1997 Marc Miribel, current president of the Company, took over the family run Fonlupt company which had a business in processing rags. Considering rags low added value, he decided to diversify into disposable protection and paper wipes. In 1998 the Company moved to a 14,000 m2 facility in Annonay, "the first step in its evolution". It launched its disposable protection brand Jet®, which soon became market leader.

In 2003 the first DESL® paper converting line was set up. By 2005, the DESL® products and the new Evadis® systems range were growing fast. This led to a necessary investment in a second facility, this one of 10,000 m2.

In 2007 the Company took a strategic turn by diversifying its sources of supply and releasing the finance needed to continue growing. Turnover and profitability increased, structures were reorganized and the company was renamed MP hygiene, reflecting its primary business: hygiene.

At the same time, the Company developed new disposable products for the industry, food, medical and sanitary sectors. It also integrated or sub-contracted manufacturing, according to quality and profitability criteria.

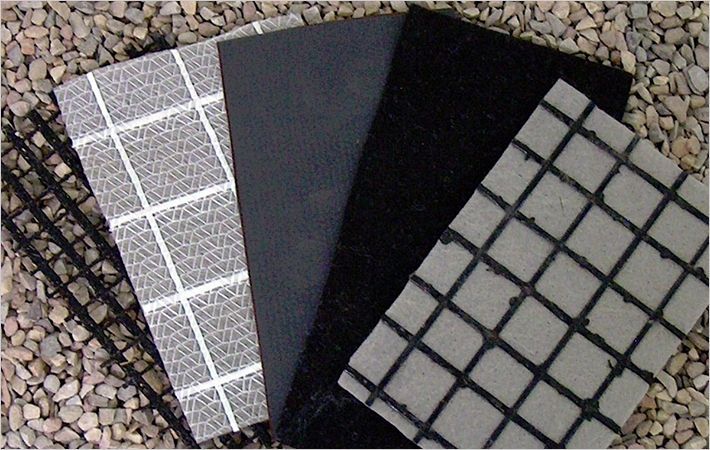

Today the Company represents five industrial divisions, with ten converting lines and three production sites over 34,000 m2. Its logistics hub of 18,000 m2 makes it possible to deliver all volumes of order, from one pallet to a whole truck, while continuous investment in research has opened the way for innovative products, such as DESL® technology, which adds resistance to paper wipes, or the Evadis® range of non-touch wiping systems.

The new Toscotec's line includes AHEAD 1.5S crescent former tissue machine with single-layer headbox, double press configuration and a Steel Yankee Dryer (TT SYD 12FT), machine auxiliaries, stock preparation plant for virgin pulp and electrification & control system.

The scope of supply includes also: a boiler plant, air compressors, turbo blowers for vacuum production, steam generator and a cascade heat exchanger system for the hood heat recovery. A three unwind stands tissue slitter rewinder TT WIND-H and an automatic roll handling system complete the supply.

The machine design speed is 1900 mpm with a net web width of 2820 mm. The project will be managed by Toscotec on an EPC (Engineering and Procurement) basis.

The greenfield project will be focused on energy savings and low emission concepts with a great attention to the environmental issues as well as to the impact on the site.

Toscotec