Trutzschler Nonwovens offers customized solutions for manufacturing of hygiene and medical applications like cotton pads, cotton roll, zigzag cotton, ear buds, cotton balls & tampon production etc., based on bleached cotton & its blends with viscose.

The unique benefits offered over the existing system are less number of machines resulting in space, power, and labor saving with better quality.Trutzschler Nonwovens offers customized solutions for manufacturing of hygiene and medical applications like cotton pads, cotton roll, zigzag cotton, ear buds, cotton balls & tampon production etc., #

Trutzschler Hygiene Card TC07H, comes with product specific attachments, these product and attachments and its result are-

Ear Buds:

• Attachment: Quad Coiler

• Preparation Requirements: Sliver 1.3 to 1.7 ktex

• Trutzschler Solution: By web splitting into 4 slivers

• Present method: Card with normal sliver delivery. Less production, lower efficiency on converting machines.

Cotton balls

• Attachment: Quad Coiler

• Preparation Requirements: Sliver 3.0 to 5.0 ktex

• Trutzschler Solution: By web splitting into 2 slivers

• Present method: Card with normal sliver delivery & draw frame passage to reach required sliver fineness

Tampon

• Attachment: Strip Forming RTSFU

• Preparation Requirements: Strip 6.5 to 15 ktex

• Trutzschler Solution: By strip forming

• Present method: Use of 3 or 4 cards with web or strip delivery

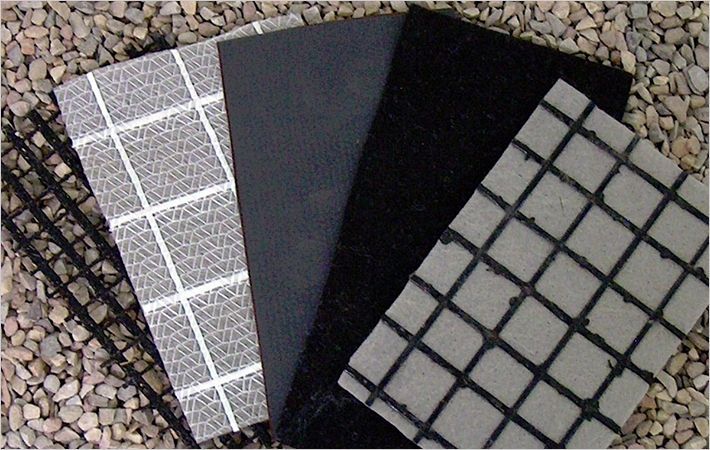

Cotton pads/ wipes

• Attachment: Shoving Unit TC-SU

• Preparation Requirements: Web weight 40 - 230 gsm

• Trutzschler Solution: By condensing the web at card delivery. Use of 2 - 4 cards depending on final web weight requirement

• Present method: Use of roller clearer card with two or three doffers.

Cotton roll & Zig Zag Cotton

• Attachment: Shoving Unit TC-SU & Folding Unit

• Preparation Requirements: 150 - 200 gms per sq. meter. Band Width: 80 to 200 depending on package weight

• Trutzschler Solution: By condensing the web at card delivery to reach weight requirement. Folding to reach band width requirement. Use of 2 - 4 cards depending efficiency requirement on converting machines.

• Present method: Use of multiple in-line cards or, use of old cards with pressed winding (local conversion), cutting & slitting manual.

Trutzschler also offer converting machines for the above applications, thus providing a one stop solution for above mentioned projects.

A.T.E. Enterprises Private Limited