New technologies in biocomposites and their applications in the automotive and construction sectors as well as in consumer products will be the focus of the “8th Biocomposites Conference Cologne”, scheduled to be held from November 14 to 15 in Cologne. The conference will present an overview of current developments, product diversity and applications.

With an average of 250 participants and 30 exhibitors, the conference has established itself as the leading international event in the sector of biocomposites. The conference is sponsored by Biowert Industrie.New technologies in biocomposites and their applications in the automotive and construction sectors as well as in consumer products will be the focus of the "8th Biocomposites Conference Cologne", scheduled to be held from November 14 to 15 in Cologne. The conference will present an overview of current developments, product diversity and applications.#

As in previous years, the “Biocomposite of the Year 2019” innovation prize will be awarded from nova-institute together with the sponsor Coperion. The focus will be on new developments that entered the market in 2018/19 or will come onto the market in 2019.

Market developments are favourable for biocomposites. The market is stable in established areas like construction and automotive and is growing strong in areas like consumer goods and packaging, with new players providing opportunities in innovative applications. The biggest increase is expected for traded biocomposite granulates for furniture, toys, consumer goods and cases, primarily in injection moulding and 3D-printing. According to Nova-Institute, the production of biocomposite granulates in Europe will double over the next 10 years.

One session of the Biocomposites Conference Cologne will focus on biocomposites in the automotive industry in cooperation with the working group for natural fibres of the AVK – Federation of Reinforced Plastics. In the automotive sector, biocomposites are primarily used for lightweight construction. The resulting lower CO2 footprint plays a crucial role in technical applications. Wood-plastic composites are mainly used for rear shelves, trims for trunks, spare wheels as well as for interior trims for doors. Natural fibre composites have a clear focus on interior trims for high-value doors and dashboards, that are processed either with thermoset or thermoplastic matrix.

Another potential market for biocomposites is small electric car manufacturers and racing cars. Such smaller car producers are not part of the established automotive value chain and they are looking for ecological lightweight materials with low carbon footprint.

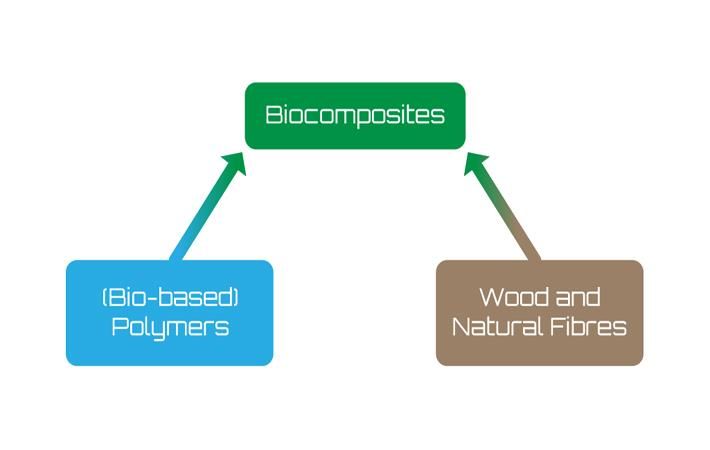

Biocomposites are seen as real alternative to plastic for consumer goods. Biocomposites contain wood or other natural fibre and a (bio-)polymer as a matrix. Various production methods including extrusion and injection as well as press moulding or 3D printing can be used. Most producers still use fossil-based polymers for producing biocomposites. But, there are a lot of bio-based polymers in the market to produce partly or fully bio-based composites which allow to use renewable carbon instead of fossil carbon. Some are biodegradable for special applications. In combination with biodegradable plastics, biocomposites are suitable for the use in agriculture, horticulture and also for applications in filter balls and coffee capsules.

Packaging is the leading application for bio-based polymers. Bio-based polymers do not differ optically from petro-based plastics. In combination with wood or natural fibres, they offer excellent opportunities for the ecological marketing of food trays, biocosmetics or detergents. (SV)

Fibre2Fashion News Desk – India