Market leader in spread tow reinforcements, Oxeon, has set a new standard for visual spread tow carbon fibre fabrics, PDESP21. The new standard makes TeXtreme’s signature square pattern more perfect to meet the most challenging visual demands. Using proprietary spreading and weaving technologies, splits, gaps and distortion are controlled.

“We always work to push our materials and technologies to meet even higher expectations from our customers. I am very proud to see our dedication to development work and continuous improvements result in a new standard for visual spread tow fabrics. By using our proprietary spreading and weaving technologies we are able to control splits, gaps, distortion etc to meet this extreme visual level for these types of material,” says Andreas Martsman, VP - marketing and sales of Oxeon AB, makers of TeXtreme.Market leader in spread tow reinforcements, Oxeon, has set a new standard for visual spread tow carbon fibre fabrics, PDESP21. The new standard makes TeXtreme's signature square pattern more perfect to meet the most challenging visual demands. Using proprietary spreading and weaving technologies, splits, gaps and distortion are controlled.#

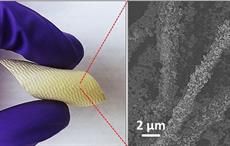

TeXtreme’s signature square pattern makes it stand out from the crowd and this new standard takes it to the next level of perfection to meet also the most challenging visual demands. Connecting it with the outstanding references and current users, the TeXtreme technology yields high-quality, high-performance, lightweight carbon fibre products that last.

Andreas continues,” We already see the value of offering these perfect looking versions of TeXtreme for applications where the visibility is most important. For example, a luxury automotive brand from England, approved it to a high enough visual standard to be willing to use it in places where drivers and passengers see it all the time, like dashboards and the door linings in their new car.”

TeXtreme technology is based on using thin flat tapes instead of round yarns, a patented process that provides unique possibilities for weight savings and performance improvements compared to other carbon fibre materials. In general, TeXtreme can reduce weight by 20-30 per cent compared to conventional carbon fibre materials, with maintained or increased levels of stiffness and/or strength. Weight saving or performance increase is not the focus for this new visual version of TeXtreme but these benefits come with any version of TeXtreme. Also, a perfect looking material is a proof of process control and precision which is crucial to meet tight tolerances and challenging goals in for example the aerospace industry.

Novel TeXtreme materials are being used by several major brands in the sporting goods market and in various industrial and advanced aero applications. (SV)

Fibre2Fashion News Desk – India