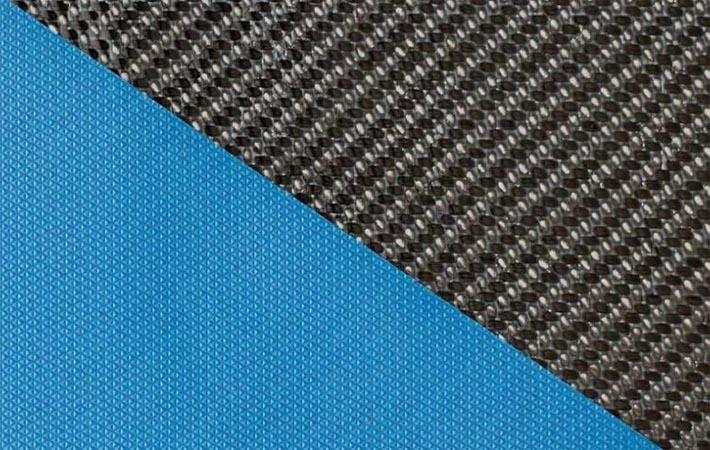

PRF Composite Materials, a manufacturer and supplier of high-performance materials, has launched its new unidirectional glass prepreg. The company says that customer feedback on its unidirectional glass prepreg is encouraging, with the new material already being selected for high end, visual quality applications due to its exceptional surface quality.

“Available in weights from 150-600 g/m2 and widths of 300mm and 600mm, our high quality unidirectional glass is now in manufacture on our RP542-4 epoxy prepreg system,” the company said.PRF Composite Materials, a manufacturer and supplier of high-performance materials, has launched its new unidirectional glass prepreg. The company says that customer feedback on its unidirectional glass prepreg is encouraging, with the new material already being selected for high end, visual quality applications due to its exceptional surface quality.#

Designed as an intermediately toughened system, complementing both our RP542-1 and highly toughened RP549 systems, RP542-4 is producing excellent results on unidirectional glass and carbon, and woven fabrics.

The company said that customer feedback on its unidirectional glass prepreg was highly positive, with this new material already being selected for high end, visual quality applications due to its exceptional surface quality.

“For 2020-2021, we are continuing to invest in significant upgrades and additions to our manufacturing and R and D lab facilities, with innovative product development remaining a central focus for the team,” it said.

PRF Composite Materials is a leading manufacturer and supplier of high-performance materials for the advanced composites industry, with a comprehensive range of products available from stock: prepreg (tooling and component), reinforcements, epoxy resin systems, release agents and kitting services. With over 35 years’ experience supplying the aerospace, motorsport, renewable energy, defence, sports and leisure, medical and marine industries, the company is now building on significant recent investment to further develop its prepreg manufacturing capability and extend range of high quality prepreg systems.

Fibre2Fashion News Desk (SV)