A team of materials scientists at Rensselaer Polytechnic Institute has been able to increase the strength of composites several-fold with an interface that is modified by a molecular layer of “nanoglue, by oscillating loads at certain frequencies. The team included researchers from multiple disciplines, based in New York, Virginia, and Grenoble, France.

The discovery may pave the way for new materials and applications. A newly published article in Nature Communications reports the unexpected discovery of the effects of loading frequency on the fracture energy of a multilayer composite involving a “nanoglue,” the use of which was also pioneered at Rensselaer.A team of materials scientists at Rensselaer Polytechnic Institute has been able to increase the strength of composites several-fold with an interface that is modified by a molecular layer of “nanoglue, by oscillating loads at certain frequencies. The team included researchers from multiple disciplines, based in New York, Virginia, and Grenoble, France.#

“Unearthing, understanding, and manipulating nanoscale phenomena at interfaces during dynamic stimuli is a key to designing new materials with novel responses for applications,” said Ganpati Ramanath, the John Tod Horton Professor of Materials Science and Engineering at Rensselaer and the lead author on the study. “Our work demonstrates that introducing a nanoglue layer at an interface of a layered composite can lead to large mechanical toughening at certain loading frequencies.”

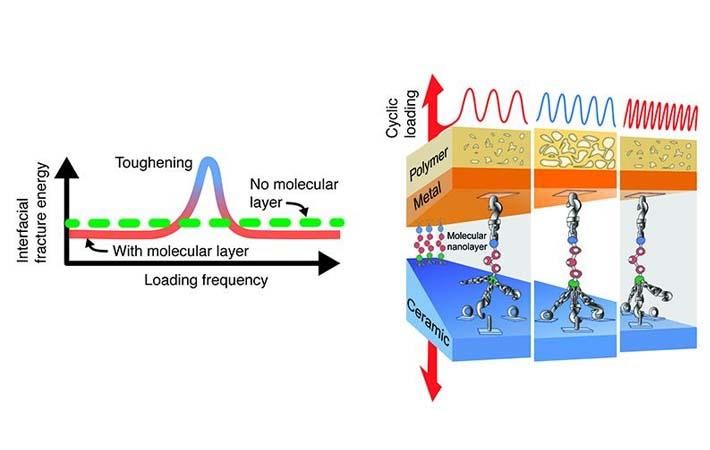

Ramanath and his team found that at certain loading frequencies, the energy required to fracture a nanoglue-modified polymer-metal-ceramic composite tripled, and exceeded the static loading fracture energy. This behaviour is unexpected and significant because fracture energy is typically lower during cyclic loading than it is during static loading. Such frequency-dependent toughening was observed only when a nanoglue layer was used to bond the metal and the ceramic.

The results also show that while the nanolayer is necessary for toughening to occur, the frequency range and the extent of toughening are primarily determined by the mechanical properties of the polymer in the composite. Specifically, the nanoglue facilitates load transfer across the metal-ceramic interface and dissipates energy in the polymer through plastic deformation, leading to an increase in fracture energy.

“Our discovery opens up an entirely new set of possibilities to design composites with novel responses using different combinations of polymers and interfacial nanolayers. For example, we could realise a completely new class of smart composites that can significantly toughen, or perhaps even self-destruct, at certain frequencies,” Ramanath said.

“Our findings of beneficiary couplings between the nanoglue effect and the properties of a constituent in a composite during cyclic loading opens a new paradigm in reliability engineering,” said co-author Michael Lane, the Billie Sue Hurst Professor of Chemistry at Emory & Henry College. “Manipulating the coupling can actually make composites more robust under just the loading conditions we have traditionally tried to avoid, and hence, can vastly expand the scope and improve the performance of composites in applications.”

The research is the product of collaboration between researchers from multiple disciplines who are based in New York, Virginia, and Grenoble, France. (SV)

Fibre2Fashion News Desk – India