Congressman Fitzpatrick congratulated US BioDesign's commitment to expanding local manufacturing job opportunities. Pennsylvania Senator Bob Mensch also cited the company's commitment to manufacturing excellence and fostering regional economic growth.

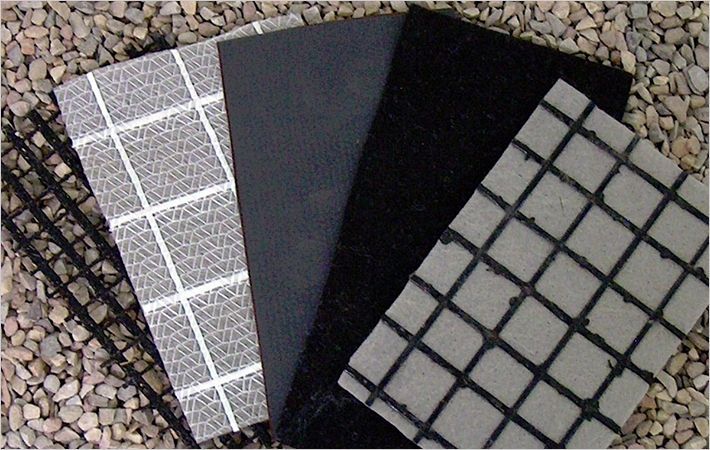

The tour spotlighted US BioDesign's highly specialized capabilities, clean room technology and state-of-the-art manufacturing equipment, which includes the world's largest medical braider and custom-designed processes for non-woven medical felts.

According to Mr. Molz, the facility expansion supports the company's business strategy for remaining competitive, despite the Affordable Care Act's economic impact on the global medical device industry.

"The Affordable Care Act mandates a 2.3% tax on the sale of medical devices which means our customers have to do more with less," said Keith Smith, Director of Business Development. "Our streamlined approach to new product development enables the most cost effective use of resources, helping medical device companies address this challenge," he continued.

According to Mr. Molz, unlike some long established suppliers to the medical device industry, US BioDesign is a new company with an agile and flexible operating structure designed to support its singular founding mission: To serve the medical device industry as a highly capable, yet cost efficient supplier of engineered medical textiles, biomedical structures and implantable fabrics. "Our business strategy," he said, "advances that mission and positions US BioDesign as the foremost industry resource for expert, highly reliable, highly capable, high quality yet cost efficient medical fabric development and manufacturing solutions."

"What you see is what you get - a smart, competitive company with an operating structure that's only as big as it needs to be, and agile and flexible enough to respond to changing industry dynamics without compromising quality or cost efficiency," commented Mr. Smith.

US BioDesign employees combine some 100 years of expertise in biomaterials and medical fabric design, development and manufacturing. "The extensive medical device industry knowledge and expertise of our leadership and engineering teams can help medical device companies control R&D costs despite current and emerging economic challenges," said Mr. Molz.

US BioDesign is the second biomedical manufacturing company founded by Mr. Molz. Keith Smith brings extensive experience in bio-materials and textile structures used for implantable medical device components, in addition to leading business development and managing strategic client relationships for US BioDesign.

US BioDesign