SGL Carbon and Elbe Flugzeugwerke, a German aircraft manufacturer, have extended their contract to supply prepregs (impregnated carbon fibre textiles) for use in the Airbus A350 cabin’s floor panels by another year, to the end of 2020. SGL Carbon has been supplying Elbe Flugzeugwerke with carbon fibre prepregs for floor panels since the A350 was launched.

The panels are produced in a sandwiched technology using several prepreg layers. The composites used must be safe and reliable under extreme conditions. The material is highly flame-resistant and complies with the aerospace industry’s fire protection regulations for interiors. Due to its low weight and its excellent strength and rigidity, the material is particularly well suited to the lightweight construction required by the aerospace industry. Carbon-fibre-reinforced plastic is significantly lighter than traditional materials such as aluminium or titanium, according to SGL.SGL Carbon and Elbe Flugzeugwerke, a German aircraft manufacturer, have extended their contract to supply prepregs (impregnated carbon fibre textiles) for use in the Airbus A350 cabin's floor panels by another year, to the end of 2020. SGL Carbon has been supplying Elbe Flugzeugwerke with carbon fibre prepregs for floor panels since the A350 was launched.#

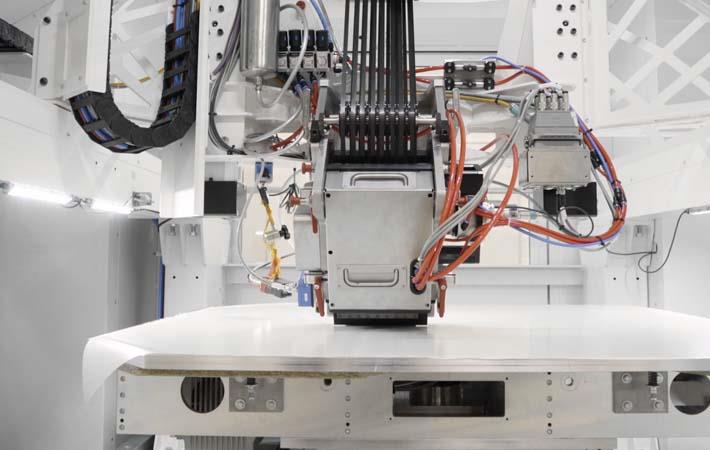

The materials are produced at the SGL Carbon site in Willich, near Düsseldorf. The plant has state-of-the-art facilities for manufacturing pre-impregnated carbon fibre and glass fibre materials, and specialises in producing prepregs for the aerospace industry.

“We are delighted to be signing this contract with a longstanding customer, thereby further strengthening a constructive working relationship based on trust. The extension of the contract also underscores our expertise regarding the technology and materials involved in the aerospace sector,” Andreas Erber, head of the aerospace segment of the business unit composites – fibres and materials at SGL Carbon said. (GK)

Fibre2Fashion News Desk – India