Shape Machining has joined hands with Ultima Forma to develop lightweight composite parts. The two are focusing to produce electroformed composite parts and have seen encouraging results. Shape was founded by former F1 chief designer Peter McCool to provide precision composite machined tooling to the motorsport, automotive and aerospace industries.

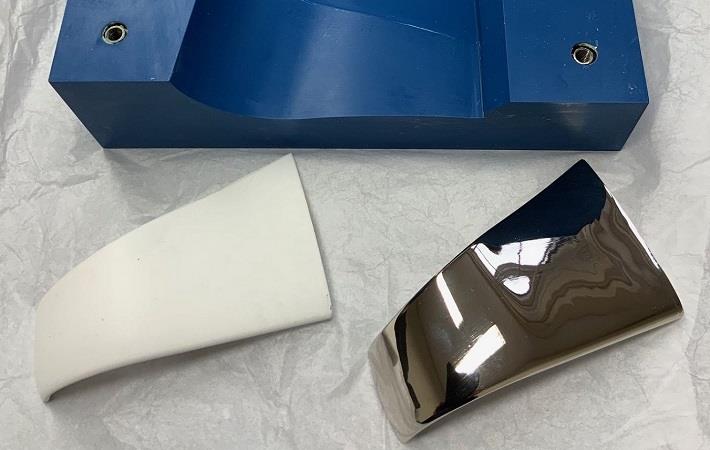

Managing director, Ryan Muller said “We have seen promising results for electroformed composite parts in terms of performance and mass. Through a similar process to RIM part manufacture, we designed and manufactured PU tooling in order for Ultima Forma to inject the tool and subsequently electroform the resulting part”.Shape Machining has joined hands with Ultima Forma to develop lightweight composite parts. The two are focusing to produce electroformed composite parts and have seen encouraging results. Shape was founded by former F1 chief designer Peter McCool to provide precision composite machined tooling to the motorsport, automotive and aerospace industries.#

The foam core weighs 14g with 100 microns of electroformed Nickel skin added, producing a high stiffness and damage tolerant composite part weighing 37g.

Muller added “We have lots of ideas of how to use this technology for composite tooling and parts. We have tried similar processes in the past with other suppliers resulting in limited success – the results we have had from our recent development are very encouraging”.

Shape designs and manufactures composite tooling and jigs to meet all budgets - from low volume prototyping jigs to full scale series production volume.

Fibre2Fashion News Desk (SV)