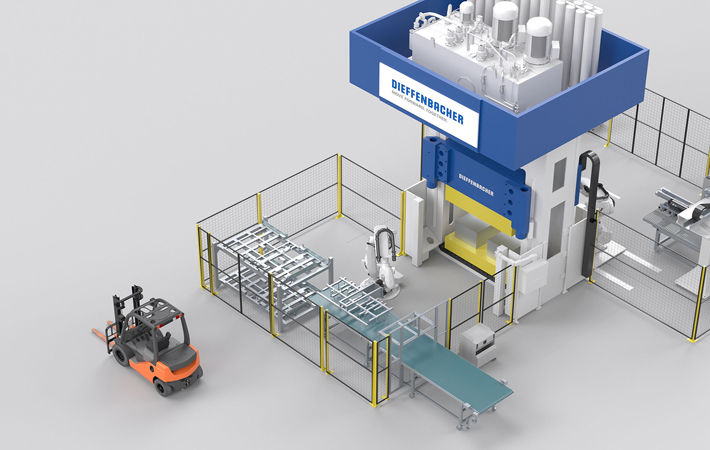

Fully automated Dieffenbacher sheet molding compound (SMC) lines are becoming increasingly popular among the parts suppliers for the automotive, logistics and construction industries. This is because these lines speed up production, reduce scrap costs and increase output. SMC processes are used by automotive parts suppliers to make composite components.

“Over the past three years, we’ve seen a huge uptick in the number of companies inquiring about automating their SMC production lines,” said Marco Hahn, director Sales of Dieffenbacher’s Composites Business Unit. “This reflects an increased desire to get away from manual processes and move toward faster and more efficient automated processes.”Fully automated Dieffenbacher sheet molding compound (SMC) lines are becoming increasingly popular among the parts suppliers for the automotive, logistics and construction industries. This is because these lines speed up production, reduce scrap costs and increase output. SMC processes are used by automotive parts suppliers to make composite components.#

SMC processes are used by automotive parts suppliers to manufacture composite components such as truck bumpers and car tailgates. For the logistics and construction industries, SMC technology is used to manufacture pallets, door modules, light wells, switch boxes and components for rail vehicles. While the vast majority of SMC applications still rely on manual processes, more companies are discovering that fully automated Dieffenbacher SMC plants provide significant increases in productivity and plant efficiency.

With manual operations or with ordinary cutting units, the time-consuming change of SMC input material causes constant production interruptions. In contrast, the Dieffenbacher quick-change system reduces changeover times to a minimum by allowing the material to be changed parallel to ongoing operation. Prepared outside the production cell, the quick-change device with the new SMC batch is moved into the plant cutting system at the push of a button and automatically inserted as soon as the previous batch has been used.

“With conventional cutting systems, a change of SMC input material takes about 10 minutes. The Dieffenbacher quick-change system saves you about six to seven minutes each time you change the SMC batch,” explained Hahn. “If you extrapolate this to a day, a week, a month or a year, you will save a significant amount of time using automated Dieffenbacher technology.”

While the manual cutting and stacking process is error-prone and time-consuming, Dieffenbacher SMC lines are equipped with automated cutting peripherals that communicate automatically with a stacking portal, enabling several complex lay-up profiles with different cutting patterns to be produced simultaneously. Active-compensation cutting automatically corrects deviations in stack weight. Weight tolerances in the semi-finished product are reliably met. This ensures maximum reproducibility even with the geometric complexity of the SMC layer structure.

Automation offers other benefits. Material residues and rejects from SMC production pollute the environment, and their disposal as hazardous waste is complicated and expensive. With flexible cutting geometries that make optimum use of the input material and minimise waste, intelligent Dieffenbacher SMC cutting technology protects the environment and reduces disposal costs.

“Compared to manual processes, fully automated Dieffenbacher SMC plants enable shorter cycle times and consistently high component quality. This results in considerable increases in productivity and significantly improved plant efficiency,” said Hahn.

Fibre2Fashion News Desk (SV)