The researchers, from the Korea Institute of Machinery and Materials (KIMM) and the Korea Advanced Institute of Science and Engineering (KAIST), used laser direct patterning technology to form laser-induced graphene (LIG) on e-textiles, successfully manufacturing graphene-based materials with world-class electrical conductivity, according to their findings published in the scientific journal ACS Nano.

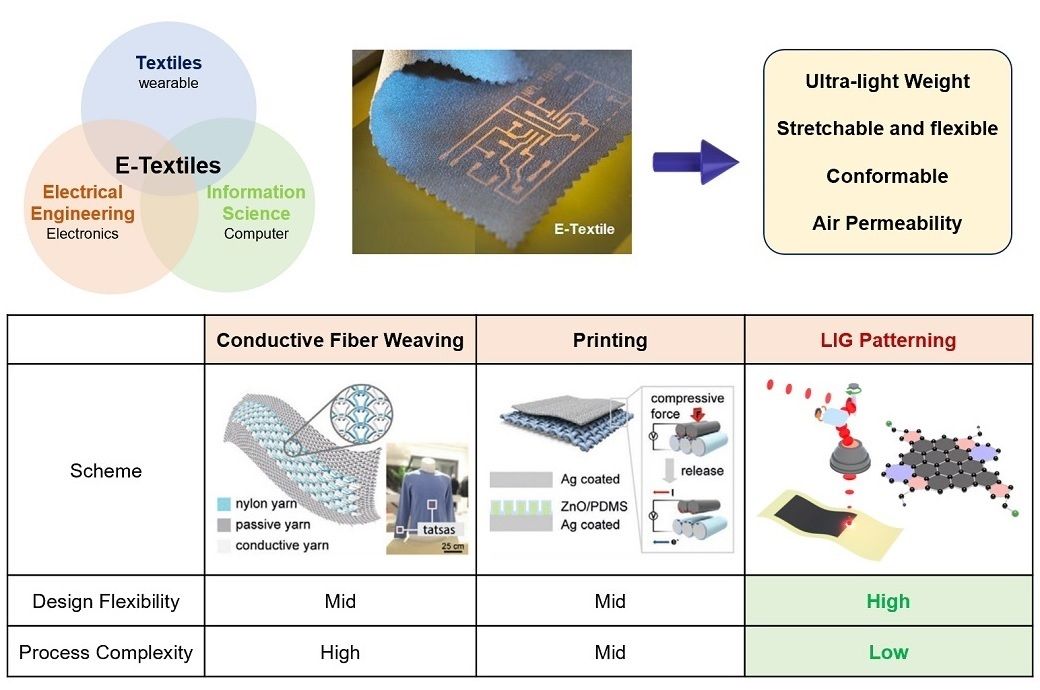

The innovation bypasses the conventional methods that rely on toxic chemicals and optical masks for patterning, thus overcoming limitations in design flexibility and mass production. The team employed femtosecond laser processing technology, which uses ultrashort lasers to fabricate materials with almost no damage, making it ideal for high-resolution patterns, KIMM said in a press release.

The breakthrough opens up new avenues for the creation of industrial and military clothing tailored for personal health management, as well as customised 'smart' clothes in the healthcare sector. Importantly, the development promises e-textiles that are not only functionally superior but also environmentally friendly.

“This technology has been developed by analysing the structures of generic fabrics and realising them as graphene-based materials that have advanced features of optimal e-textiles,” said principal researcher Soongeun Kwon of the KIMM.

Fibre2Fashion News Desk (NB)